Ku soo dhawoow boggayaga internetka!

Cabbiraadda Warshadaha iyo Dareemaha Saxnaanta ee Tankii S-Nooca Dareemaha Heerkulka Sare

Sharaxaadda Badeecada

Dareemaha Heerkulka Nooca S (0-1300℃, Dhererka 250mm)

Dulmar Guud oo ku saabsan Badeecada

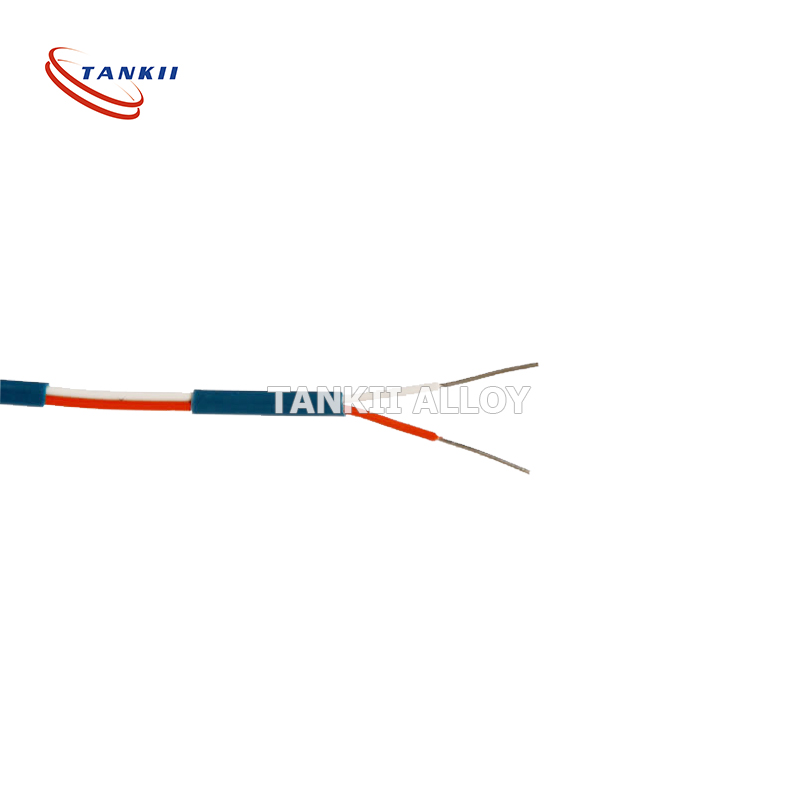

Dareemaha heerkulka nooca S-nooca ah (platinum-rhodium 10%-platinum, Pt10Rh/Pt) ee Tankii Alloy Material waa qayb cabbir heerkul sare oo sax ah oo loo sameeyay jawi kuleyl aad u daran. Iyada oo leh naqshad loogu talagalay dhererka guud ee 250mm, tuubo ilaalin ah oo 7-8mm ah oo dibadda ah, iyo silig gudbiye oo dhexroorkiisu yahay 0.2mm, dareemahani wuxuu gaaraa ogaanshaha heerkulka saxda ah ee 0-1300℃ iyada oo loo marayo saameynta Seebeck ee birta sharafta leh. Waxay isku daraysaaxasillooni heerkul sare oo aad u fiican,hoos u dhac cabbir yar, iyocimri dherer dhismeed oo adag— taasoo ka dhigaysa doorashada ugu habboon ee hababka heerkulka sare sida la socodka heerkulka foornada warshadaha, qaabaynta heerkulka daaweynta kulaylka, iyo tijaabinta isku halaynta heerkulka sare ee qaybaha elektaroonigga ah.

Magacaabista Heerka iyo Aasaaska Dhismaha

- Darajada DareemahaNooca S (IEC 60584-1 Fasalka 1; oo u dhiganta ANSI/ASTM E230 Nooca S) - kuleyliyaha birta sharafta leh oo leh Pt10Rh (elektroodh togan) iyo koronto-dhaliyeyaasha Pt (elektroodh taban) saafi ah

- Tilmaamaha Muhiimka ahKala duwanaanshaha heerkulka: Heerkulka 0-1300℃ (isticmaalka muddada gaaban ilaa 1400℃ muddo ≤30 daqiiqo ah); dhererka guud waa 250mm (cabbirka dhererka dhammaadka 50mm, dhererka siligga rasaasta 200mm); dhexroorka dibadda ee tuubada ilaalinta dhoobada waa 7-8mm (dhumucda derbiga waa 1.2-1.5mm); dhexroorka siligga gudbiyaha waa 0.2mm (dulqaad ±0.01mm)

- Heerarka u Hoggaansan: IEC 60584-1 (fasalka saxnaanta thermocouple), GB/T 1672-1997 (thermocouples-ka platinum-rhodium), ASTM E230-19 (heerka loogu talagalay thermocouples-ka birta sharafta leh)

- Soo-saaraha: Tankii Alloy Material, oo shahaado haysta ISO 9001 iyo ISO 14001, oo leh dhalaalinta birta sharafta leh iyo awoodaha cabbiraadda dareemayaasha

Faa'iidooyinka Muhiimka ah (loogu talagalay 0-1300 ℃ & Tilmaamaha Dhismaha)

1. Saxnaanta iyo Xasilloonida Cabbiraadda Heerkulka Sare

Waxay qaadataa 99.99% silig koronto oo Pt10Rh/Pt ah oo saafi ah (dhexroor 0.2mm ah) oo leh qaab isku mid ah oo daawaha ah - saxnaanta cabbirku waxay gaartaa Heerka 1 (qalad ≤±1.5℃ ah 0-600℃, ≤±0.25% t at 600-1300℃, t= heerkulka la cabbiray). Ka dib 1000 saacadood oo hawlgal joogto ah at 1200℃, qulqulka awoodda kuleyliyaha waa <3μV (oo u dhiganta qaladka heerkulka <0.4℃) - aad uga sarreeya kuleyliyaha nooca K (qulqulka >10μV at 800℃) waxayna ku habboon tahay la socodka heerkulka sare ee muddada dheer.

2. Waaranaanta Qaab-dhismeedka ee La Hagaajiyay

- Tube Ilaalinta Dhoobada: 7-8mm dhexroor dibadda ah oo ah dhoobada aluminium sare leh (Al₂O₃ content ≥95%) oo leh iska caabin heerkul sare ah ilaa 1600℃, xoog cadaadis leh ≥150MPa—si wax ku ool ah u kala soocaya birta dhalaalaysa, boodhka foornada, iyo gaasaska daxalka leh iyadoo la hubinayo hufnaanta wareejinta kulaylka (kuleylka la qaadan karo ≥20 W/(m·K) heerkul ah 800℃).

- Naqshadeynta Isku xirka iyo Kondurka: Qalabka cabbiraadda dhexroorka 0.2mm wuxuu dheellitiraa dabacsanaanta iyo xoogga heerkulka sare (xoogga jiidista ≥350MPa 25℃, ≥150MPa 1300℃); dhammaadka cabbirku wuxuu qaataa alxanka booska (dhexroorka booska alxanka 0.3-0.4mm) si loo hubiyo wax soo saarka awoodda kulaylka oo deggan iyada oo aan lahayn iska caabinta taabashada.

- Isku-xidhka Dhererka Guud: Dhererka guud ee 250mm (dhammaadka cabbirka 50mm + silig rasaas ah 200mm) ayaa loo habeeyay rakibidda darbiga dhinaca foornada warshadaha - waxay ka hortagtaa foorarsiga xad-dhaafka ah ee siligga rasaasta iyadoo la hubinayo in dhammaadka cabbirku uu gaaro aagga heerkulka xudunta.

3. Kalsoonida La-waafajiyay ee Codsiga

Dareemuhu wuxuu leeyahay iska caabin oksaydh oo wanaagsan (wuxuu sameeyaa filim ilaalin PtO₂ oo cufan heerkulka sare) iyo iska caabin shoogga kulaylka (wuxuu u adkeysan karaa isbeddelka heerkulka 500℃/daqiiqo iyada oo aan la dillaacin tuubada dhoobada ah). Fiilada rasaastu waxay qaadataa dahaarka Teflon heerkulka sare (heerkulka hawlgalka -60℃ ilaa 260℃) si looga hortago wareegyada gaagaaban ee aqoon-is-weydaarsiyada heerkulka sare, terminaalkuna wuxuu ku qalabaysan yahay isku xire M12 caadi ah si loogu xiro si dhakhso ah gudbiyeyaasha heerkulka.

Tilmaamaha Farsamada

| Sifada | Qiimaha (Caadi ahaan) | Muhiimadda Codsiga |

|---|---|---|

| Nooca Dareemaha | Nooca S (Pt10Rh/Pt) | Birta sharafta leh ee saafiga ah waxay hubisaa xasilloonida heerkulka sare |

| Kala duwanaanshaha Heerkulka | 0-1300℃ (si joogto ah); 0-1400℃ (muddo gaaban ≤30 daqiiqo) | Waxay dabooshaa inta badan hababka heerkulka sare ee warshadaha |

| Saxnaanta Cabbirka | Fasalka 1aad: ±1.5℃ (0-600℃); ±0.25% t (600-1300℃) | Waxay buuxisaa shuruudaha daaweynta kulaylka saxda ah (tusaale ahaan, daminta qaybaha baabuurta) |

| Wadarta Dhererka | 250mm (La habeeyey) | Loogu habeeyay rakibidda darbiga dhinaca foornada |

| Qeexitaanka Tuubada Dhoobada | Dhexroorka dibadda 7-8mm | Ilaalinta dheelitirka iyo hufnaanta wareejinta kulaylka |

| Dhexroorka Wire-ka Koronto | 0.2mm (dulqaad ±0.01mm) | Hubinta xasilloonida iyo dabacsanaanta awoodda kuleyliyaha korontada |

| Awoodda Heerkulka Korontada (1000℃) | 10.591mV (marka la barbar dhigo 0℃ isgoyska tixraaca) | Wuxuu u hoggaansamayaa qiimayaasha cabbiraadda heerka IEC 60584-1 |

| Waqtiga Jawaabta (τ₅₀) | ≤2s (hawada ku jirta 800℃) | Waxay la qabsataa isbeddellada heerkulka firfircoon ee daaweynta kulaylka |

| Nolosha Adeegga (1200℃ joogto ah) | ≥1000 saacadood | Waxay yareysaa soo noqnoqoshada dayactirka foornada warshadaha |

Qeexitaannada Badeecada

| Shay | Faahfaahinta | Faa'iidada Waxqabadka |

|---|---|---|

| Waxyaabaha Tube Ilaalinta | 95% dhoobada aluminiumka sare leh | Iska caabinta heerkulka sare iyo iska caabinta daxalka |

| Dahaarka Kondurka | Kuul dhoobada alumina oo saafi ah (qaybta 250℃); Teflon (qaybta heerkulka qolka) | Waxay ka hortagtaa wareegga gaaban heerkulka sare |

| Isku xiraha Terminalka | Isku xiraha biyaha aan biyuhu karin ee M12 (heerka ilaalinta IP65) | Rakibaadda degdegga ah iyo boodhka/biyo-celinta |

| Shahaadada Kala-hagaajinta | Warbixinta habaynta ee NIST-la raadraaci karo (ikhtiyaar) | Waxay buuxisaa shuruudaha xaqiijinta mitirka |

| Baakad | Xumbo shoog u adkaysata + sanduuq kartoon ah; baakad hal gabal ah | Waxay ka hortagtaa jabka tuubada dhoobada ah inta lagu jiro rarista |

| Habayn | Dhererka guud (100-1000mm); walxaha tuubada dhoobada ah (99% alumina 1600℃); nooca isku xirka (isku xirka yar ee aaladaha elektarooniga ah) | Waxay la qabsataa baahiyaha rakibaadda gaarka ah iyo codsiga |

Xaaladaha Codsiga Caadiga ah

1. Geedi socodka Heerkulka Sare ee Warshadaha

Waxaa loo isticmaalaa la socodka heerkulka foornada birta lagu daweeyo kulaylka (tusaale ahaan, daminta birta aan miridhku lahayn ee 900-1100℃) iyo foornada sintering-ka dhoobada ah (1200-1300℃) - tuubada dhoobada ah ee 7-8mm waxay ka hortagtaa nabaad-guurka boodhka foornada, saxnaanta heerka 1aadna waxay hubisaa tayada badeecada oo joogto ah.

2. Tijaabinta Kalsoonida Qaybaha Elektarooniga ah

Tijaabooyinka gabowga heerkulka sare ee jajabyada semiconductor-ka iyo modules-ka awoodda (0-1200℃) - gudbiyaha khafiifka ah ee 0.2mm iyo waqtiga jawaabta degdegga ah (≤2s) si sax ah ayuu u qabtaa isbeddellada heerkulka ku meel gaarka ah inta lagu jiro kuleylinta qaybaha, isagoo bixinaya taageero xog ah oo loogu talagalay qiimeynta isku halaynta.

3. Cabbiraadda Heerkulka Sare ee Dareemaha Cadaadiska

Sida tixraaca heerkulka ee nidaamyada cabbiraadda heerkulka sare ee dareemayaasha cadaadiska (tusaale ahaan, hagaajinta dareemayaasha cadaadiska matoorka baabuurta ee 800-1000℃) - wax soo saarka awoodda thermoelectric ee deggan wuxuu hubiyaa saxnaanta cabbiraadda dareemayaasha cadaadiska.

4. Cilmi-baarista Heerkulka Sare ee Shaybaarka

Waxaa loo isticmaalaa shaybaarrada sayniska agabka si loo tijaabiyo isbeddelka heerka heerkulka sare (0-1300℃) - dhererka 250mm wuxuu ku habboon yahay foornada kursiga keydka, iyo habaynta ikhtiyaariga ah ee NIST waxay buuxisaa shuruudaha raadinta xogta cilmi-baarista.

Hubinta Tayada iyo Taageerada Farsamada

Tankii Alloy Material waxay hirgelisaa xakamaynta tayada saddex-marxalad ah ee dareemayaasha heerkulka nooca S-ga ah:

- Kormeerka KondurkaFalanqaynta isku-dhafka daawaha XRF (waxay hubisaa in Pt10Rh ay ka kooban tahay 9.5-10.5%) iyo tijaabada iska caabbinta baaritaanka afar-dhibcood (waxay xaqiijinaysaa daahirnimada).

- Tijaabada Isku-dubaridka: Hagaajinta heerkulka sare ee foornada saxda ah (saxnaanta heerkulka ±0.1℃) iyo tijaabinta shoogga kulaylka (50 wareeg oo ah 25℃-1300℃).

- Xaqiijinta Kama Dambeysta ah: Tijaabo hawlgal oo joogto ah oo 24-saac ah oo ah 1200℃ si loo xaqiijiyo waxqabadka qulqulka iyo tijaabada biyaha ee isku xirka (IP65).

Shaybaarro bilaash ah (oo leh warbixin cabbiraad) iyo hagitaan rakibaad goobta ah ayaa la heli karaa marka la codsado. Kooxdayada farsamada waxay bixiyaan xalal gaar ah sida hagaajinta dhererka dareemayaasha ee foornada gaarka ah iyo hagitaan isku mid ah oo leh gudbiyeyaasha heerkulka si loo hubiyo waxqabadka cabbirka ugu wanaagsan.

Halkan ku qor fariintaada oo noo soo dir

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare