Ku soo dhawoow boggayaga internetka!

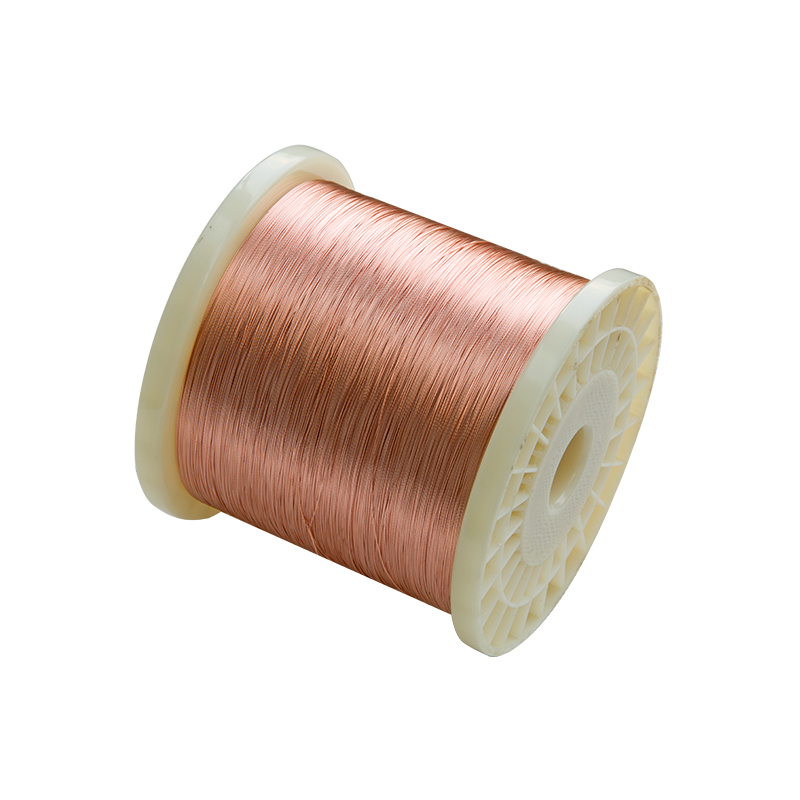

Tankii 1.0mm Silig Naxaas ah oo Qasacadaysan T2 Naxaas Cas oo Ka-hortagga Oksaydheynta & Gudbinta Aad u Fiican

Sharaxaadda Badeecada

Silig Naxaas ah oo 1.0mm ah oo Qasacadaysan (Xuduudda Naxaasta Cas ee Saafiga ah, Dahaarka Tin ee 3-5μ)

Dulmar Guud oo ku saabsan Badeecada

Sida gudbiye koronto oo lagu kalsoonaan karo oo ka socda Tankii Alloy Material,Silig naxaas ah oo 1.0mm ah oo qasacadaysanWaxay isku daraysaa laba faa'iido oo asaasi ah: gudbinta aadka u sarreysa ee naxaasta cas ee saafiga ah (heerka T2) iyo ilaalinta ka hortagga daxalka ee dahaarka saxanka saxda ah ee 3-5μ. Waxaa lagu sameeyay habka diyaarinta kulul ee joogtada ah ee Huona - oo lagu qalabeeyay la socodka dhumucda waqtiga dhabta ah iyo xakamaynta heerkulka - siliggu wuxuu hubiyaa in lakabka daasadda uu si isku mid ah ugu dheggan yahay xudunta naxaasta adag ee 1.0mm, ma jiraan godad ama dhibco khafiif ah. Waxay xallisaa laba qodob oo muhiim ah oo xanuun ah oo ka mid ah siligga naxaasta qaawan: hoos u dhaca socodka oksaydhka iyo alxanka oo liita, taasoo ka dhigaysa mid muhiim u ah isku xirka korontada oo u baahan xasillooni muddo dheer ah, isu-imaatin fudud, iyo iska caabbinta jawiga qoyan/warshadaha.

Shahaadooyinka Heerka & Agabka

- Darajada Koontaroolaha: T2 naxaas cas oo saafi ah (wuxuu waafaqsan yahay GB/T 3956-2008; oo u dhiganta ASTM B33, IEC 60288 Fasalka 1aad)

- Heerka Dahaadhka Tin: GB/T 4910-2009, IEC 60317-2 (ma laha rasaas: Pb ≤0.005%, Sn ≥99.9%)

- Shahaadooyinka Tayada: U hoggaansan RoHS 2.0, nidaamka maaraynta tayada ISO 9001, oggolaanshaha baaritaanka deegaanka ee SGS

- Soo-saarahaTankii Alloy Material (15+ sano oo waayo-aragnimo ah oo ku saabsan farsamaynta kontaroolaha naxaasta)

Faa'iidooyinka Waxqabadka Muhiimka ah

1. Konduriyaha Naxaasta Cas ee Saafiga ah: Kondurinta Aan La Midayn

- Korontada Qaboojinta: ≥98% IACS (20℃), oo aad uga badan naxaasta la isku daray (tusaale ahaan, daawaha CuNi: ~20% IACS) iyo aluminium (61% IACS). Waxay hubisaa hoos u dhaca danabka ee wareegyada danabka hooseeya (tusaale ahaan, fiilooyinka baabuurta ee 12V, fiilooyinka USB ee 5V) iyo gudbinta calaamadaha degdega ah ee dareemayaasha.

- Dhaqdhaqaaqa Farsamada: Dheereynta ≥30% (25℃) iyo xoogga jiidista ≥200 MPa. Waxay u adkeysan kartaa foorarsiga soo noqnoqda (tijaabada leexashada 180° ≥10 jeer iyada oo aan la jabin) si loogu isticmaalo fiilooyinka meelaha cidhiidhiga ah (tusaale ahaan, qaybaha gudaha ee qalabka, isku xirka cidhifka PCB).

2. Dahaarka Tin ee Sax ah ee 3-5μ: Ilaalinta La Beegsanayo

- Caqabadda Ka-hortagga OksaydhayntaLakab qasacadaysan oo cufan ayaa hawada/qoyaanka ka xannibaya inay taabtaan naxaasta, taasoo ka hortagaysa sameynta oksaydh naxaas ah oo gudbiya (CuO/Cu₂O). Xitaa qoyaanka 80% muddo 12 bilood ah, siliggu wuxuu ilaaliyaa ≥97% gudbinta bilowga ah (marka la barbar dhigo naxaasta qaawan: wuxuu hoos ugu dhacaa 85% 3 bilood gudahood).

- La xoojiyay isku-dhafka: Barta dhalaalka ee yar ee qasacadda (232℃) waxay suurtogal ka dhigaysaa "qoynta degdegga ah" inta lagu jiro alxanka - looma baahna nadiifinta ka hor ama firfircoonida qulqulka. Waxay yareysaa waqtiga isu imaatinka PCB 40% marka la barbar dhigo naxaasta qaawan (taas oo u baahan ka saarista oksaydhka iyada oo loo marayo shiididda/kiimikada).

- Naqshad Dhumucda DheelitiranDhumucda 3-5μ waxay ka hortagtaa laba daran: dahaarka khafiifka ah (<3μ) ma dabooli karo cilladaha naxaasta, halka dahaarka qaro weyn (>5μ) ay ka dhigayaan siligga mid jajaban (oo u nugul inuu dillaaco inta lagu jiro foorarsiga).

Tilmaamaha Farsamada

| Halbeegga | Qiime Faahfaahsan |

| Dhexroorka Magacaaban (Guud ahaan) | 1.0mm (koronto-qaadaha: ~0.992-0.994mm; dahaarka daasadda: 3-5μ) |

| Dulqaadka Dhexroorka | ±0.02mm |

| Dhumucda dahaadhka qasacadaysan | 3μ (ugu yaraan) - 5μ (ugu badnaan); isku mid ahaanshaha dhumucda: ≥95% (ma jiro meel <2.5μ) |

| Qaboojinta Korontada (20℃) | ≥98% IACS |

| Xoogga Tijaabada | 200-250 MPa |

| Kordhinta Nasashada | ≥30% (L0 = 200mm) |

| Ku dhegga Tin | Ma jiro diir/jeexitaan ka dib qalooca 180° (radius=5mm) + tijaabada cajaladda (3M 610 cajalad, ma jiro haraaga qasacadda) |

| Iska caabinta Daxalka | Waxay ka gudubtay tijaabada buufinta cusbada ASTM B117 (48 saacadood, 5% NaCl, 35℃) - miridhku ma casaado, nabarro daasad ah ayaa ka soo baxaya |

| Heerkulka Hawlgalka Kala Duwan | -40℃ (dabacsanaan heerkul hoose, dillaac la'aan) ilaa 105℃ (isticmaalka joogtada ah, dhalaalid qasacad ma jirto) |

Sahayda Alaabta & Habaynta

| Shay | Faahfaahinta |

| Foomka Bixinta | Kontarool adag (caadi); kontarool xanniban (gaar ahaan: 7/0.43mm, 19/0.26mm) |

| Qaabeynta Spool | 500m/1000m halkii boolal (qalabka boolal: ABS balaastig ah, dhexroor: 200mm, godka xudunta: 50mm) |

| Dhammaadka Dusha Sare | Qasacad dhalaalaya (sida caadiga ah); Qasacad matte ah (loogu talagalay codsiyada ka hortagga dhalaalka) |

| Daaweyn Dheeraad ah | Dahaarka ikhtiyaariga ah (PVC/XLPE/Silicone, dhumucdiisuna waa: 0.1-0.3mm, midab: madow/casaan/buluug) |

| Baakad | Bacda aluminiumka ee shaabadaysan (qoyaanka ka ilaalisa) + kartoonka dibadda (oo leh qalajiye, ka hortagga saamaynta) |

Xaaladaha Codsiga Caadiga ah

- Qalabka GurigaFiilooyinka gudaha ee mashiinnada dharka lagu dhaqo (qoyaanka u adkaysta), qaboojiyeyaasha (dabacsanaanta heerkulka hooseeya), iyo foornooyinka microwave-ka (iska caabbinta kulaylka ilaa 105℃).

- Elektaroonikada Gawaarida: Saldhigyada isku xirka ee baytariyada baabuurta (ka hortagga daxalka), fiilooyinka dareemayaasha (calaamad deggan), iyo nidaamyada macluumaadka gaariga dhexdiisa (hoos u dhaca danabka hooseeya).

- PCB & Elektarooniga Macaamiisha: Alxanka godka dhex mara ee looxyada Arduino/Raspberry Pi, qalabka fiilooyinka USB-C, iyo fiilooyinka xarigga LED (isku-dubarid fudud).

- Xakamaynta WarshadahaFiilooyinka loogu talagalay guddiyada PLC (iska caabbinta qoyaanka warshadaha) iyo sahayda korontada ee danab-yar (lumitaanka tamarta ugu yar).

- Qalabka CaafimaadkaFiilooyinka gudaha ee qalabka ogaanshaha ee la qaadi karo (oo aan lahayn rasaas, oo u hoggaansan heerarka iswaafajinta noolaha) iyo bambooyin caafimaad oo yaryar (laabasho dabacsan).

Hubinta Tayada ee ka timid Tankii Alloy Material

Dufcad kasta oo ka mid ah silig naxaas ah oo 1.0mm ah ayaa mara saddex kormeer oo muhiim ah:

- Tijaabada Dhumucda Tin: Falanqeeyaha iftiinka raajada (XRF) (saxnaanta: ±0.1μ) – 5 dhibcood oo muunad qaadis ah halkii dhibicba.

- Imtixaanka Gudbinta: Tijaabiyaha baaritaanka afar-dhibcood leh (saxnaanta: ±0.5% IACS) – 3 muunad oo dufcaddiiba ah.

- Imtixaanka Farsamada: Mashiinka tijaabada guud (taagista/dheeraynta) + tijaabiyaha qalooca (ku dhejinta) - 2 muunad dufcaddiiba.

Shaybaarro bilaash ah (dherer 1m ah, 2-3 xabbo halkii qeexitaan) iyo Warbixinnada Tijaabada Agabka oo faahfaahsan (MTR) ayaa la heli karaa marka la codsado. Kooxdayada farsamada waxay bixisaa taageero 1-on-1 ah oo loogu talagalay shuruudaha gaarka ah (tusaale ahaan, xulashada walxaha dahaarka ee codsiyada heerkulka sare, naqshadda kontaroolada ee xayiran ee fiilooyinka dabacsan).

Halkan ku qor fariintaada oo noo soo dir

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare