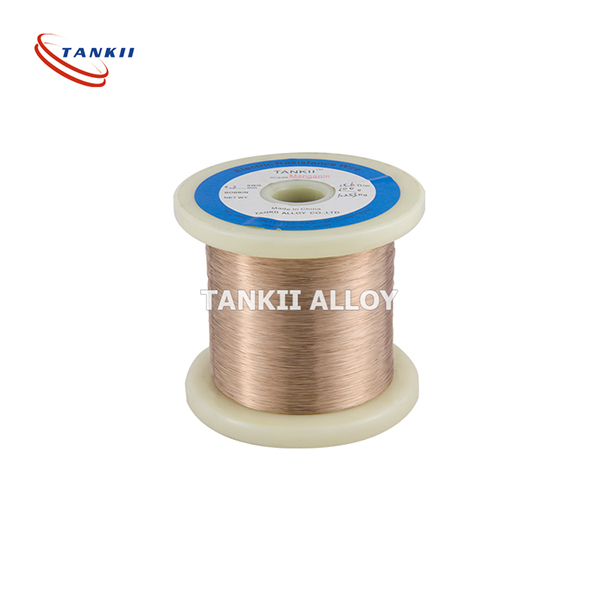

Tankii 0.19*25mm 6J13 Manganin Alloy Strip Resistivity Ultra-Stable

Xarigga daawaha manganin ee 6J13 (0.19mm × 25mm), oo ah badeecad daawaha iska caabbinta saxda ah oo laga sameeyay Tankii Alloy Material, waa xariijin shaqo oo khafiif ah oo laga sameeyay daawaha manganin ee Mn-Cu-Ni. Iyada oo loo marayo dhalaalinta faakuumka ee horumarsan, duubista qabow ee saxda ah ee badan, iyo hababka qaboojinta ee kala qaybsan, xariijintani waxay ku guulaysataa xakamaynta cabbirka aadka u adag (dhumucda 0.19mm ±0.002mm, ballac 25mm ±0.1mm) iyo sifooyin koronto oo joogto ah.

- Darajada Daawaha: 6J13 (Daawada saxda ah ee manganin ee Shiinaha; oo loo habeeyay waxqabadka rogidda ee dhuuban)

- Tilmaamaha Cabbirka: Dhumucda 0.19mm × 25mm ballac (la habeyn karo, laakiin qalabkan go'an wuxuu la mid yahay qalabka shaambaynta ee qaybaha yar yar ee caadiga ah)

- Isku-dubarid Caalami ah: Waxqabadka oo la jaanqaadaya xariijimaha khafiifka ah ee DIN 17471 CuMn12Ni2, oo leh maaddada Mn ee la hagaajiyay (12.0-13.0%) si kor loogu qaado isku-dubaridka cabbirka khafiifka ah

- Heerarka u Hoggaansan: GB/T 1234-2019 (xariijimaha daawaha iska caabbinta) + GB/T 2059-2021 (xariijimaha daawaha naxaasta ah) + IEC 60404-8-2 (qaybaha iska caabbinta saxda ah)

- Soo-saare: Tankii Alloy Material, oo shahaado haysta ISO 9001 iyo RoHS, oo leh khadad gaar ah oo bir ah oo khafiif ah (dhumucda ugu yar ee duubista 0.01mm)

- Saxnaanta Dhumucda ee Yaraynta: Dhumucda 0.19mm waxay ku dhacdaa "dheelitirka dahabka ah" ee aaladaha yaryar - kuwa ka khafiifsan 0.25mm strips (hoos u dhig mugga qaybaha 24%) iyadoo laga fogaanayo jilicsanaanta strips-ka aadka u khafiifsan (<0.15mm) ee dillaaca inta lagu jiro shaambada.

- Ballaca Cidhiidhiga ah ee loogu talagalay Shaambada Dufcadda: Ballaca 25mm wuxuu la mid yahay 4-6 qaybood oo ah shaambada micro-shunt (cabirka dhimaha kasta ~ 4mm) xarig kasta, taasoo suurtogalinaysa in hal mar shaambad lagu sameeyo 2000+ qaybood oo yaryar 100m kasta - taasoo yareynaysa qashinka agabka 30% marka la barbar dhigo isticmaalka xargaha ballaaran ee 50mm ee qaybaha yaryar.

- La qabsiga aadka u Fiican: Qaab-dhismeedka isku midka ah ee xarigga (cabirka hadhuudhka ≤20μm) iyo dusha sare ee dhalaalaya ee la buufiyay (Ra ≤0.15μm) waxay taageeraan qallajinta kiimikada aadka u fiican - ballaca xariiqda ugu yar ee la qooyay ilaa 0.02mm.

- Joogto Shaambadaysan oo Xasilloon: Ka dib 5000 oo jeer oo shaambad joogto ah la sameeyo (oo la jaanqaadaya wax soo saarka tirada), kala duwanaanshaha dhumucda xarigga waa <0.001mm, leexashada iska caabbinta ee qaybaha shaambadda lehna waa ≤0.05%.

- Naqshadeynta Kaydinta Agabka: Ballaca cidhiidhiga ah ee 25mm ee go'an wuxuu meesha ka saarayaa jarista labaad (tallaabo caadi ah oo loogu talagalay xariijimaha ballaaran), isagoo dhimaya kharashyada habaynta 18% isla markaana soo gaabinaya wareegyada keenista 3-5 maalmood.

- Heerkul laba-geesood ah Ikhtiyaar: Waxay bixisaa heerkul jilicsan (la qaboojiyey, dheereyn ≥25%) iyo heerkul badh-adag (dheereyn 15-20%) ah oo loogu talagalay habab kala duwan.

| Sifada | Qiimaha (Caadi ahaan) | Muhiimadda Codsiga Yar |

|---|---|---|

| Halabuurka Kiimikada (wt%) | Cu: 82.0-86.0%; Mn: 12.0-13.0%; Ni: 2.0-3.0%; Feer: ≤0.5% | Waxyaabaha Mn ee la hagaajiyay si looga hortago dildilaaca khafiifka ah inta lagu jiro rogrogidda |

| Dhumucda | 0.19mm (dulqaad: ±0.002mm) | Waxay hubisaa iska caabin isku mid ah oo ka timaadda micro-shunts (ka fogaanshaha eexda hadda jirta) |

| Ballaca | 25mm (dulqaad: ±0.1mm) | Waxay u dhigantaa 4-6 qaybood oo ah micro-dies si loogu shaambadeeyo dufcadaha |

| Iska caabin (20℃) | 0.44±0.04 μΩ*m | Isu dheellitiran 1-5A micro-shunts (oo caan ku ah elektaroonigga macaamiisha) |

| TCR (-40℃ ilaa 140℃) | ±10 ppm/℃ | Xasilloon oo loogu talagalay qalabka elektaroonigga macaamiisha (heerkulka hawlgalka: -10℃ ilaa 60℃) |

- Qalabka Elektarooniga Macaamiisha oo si dhakhso leh u dallacaya: Qalabka korontada ku shaqeeya ee loogu talagalay dallacaadaha taleefanka casriga ah ee 65W (dhumucdiisu waa 0.19mm waxay ku habboon tahay naqshadda khafiifka ah ee dallacaadda, ballaca 25mm wuxuu taageeraa shaambadeynta dufcadda ee 4 shunt halkii xarigba).

- Dareemayaasha Caafimaadka ee La Xidhi Karo: Walxaha iska caabbinta ee dareemayaasha garaaca wadnaha ee saacadda caqliga leh (caqliga jilicsan wuxuu suurtageliyaa leexashada radius 0.38mm, ballac cidhiidhi ah 25mm wuxuu yareeyaa qashinka agabka).

- Xididdada Dareemaha IoT: Shabakadaha iska caabiya yaryar ee dareemayaasha heerkulka/qoyaanka bilaa-waayirka ah (qalabaynta aadka u fiican waxay taageertaa ballaca xariiqda 0.02mm).

- Baabuurta Micro-Electronics: Xariijimo dareemayaal hadda jira oo loogu talagalay qaybaha dallacaadda USB-ga ee gaariga dhexdiisa (xariiq adag oo badh ah ayaa hubiya saxnaanta shaabadeynta meelaha taabashada).

Tankii Alloy Material waxay hirgelisaa "xakamaynta tayada micro-saxnaanta" ee 6J13 strips (0.19 × 25mm): duub kasta wuxuu maraa cabbirka dhumucda laysarka (100 dhibcood oo muunad ah/m), kormeerka qallafsanaanta dusha sare (qaybtii 5m), iyo tijaabinta jilitaanka micro-shamping (100 muunad dufcaddiiba). Muunado bilaash ah (100mm × 25mm, dabeecad jilicsan/nus adag ikhtiyaari ah) iyo warbixinnada tijaabada micro-shamping ayaa la heli karaa marka la codsado.

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare