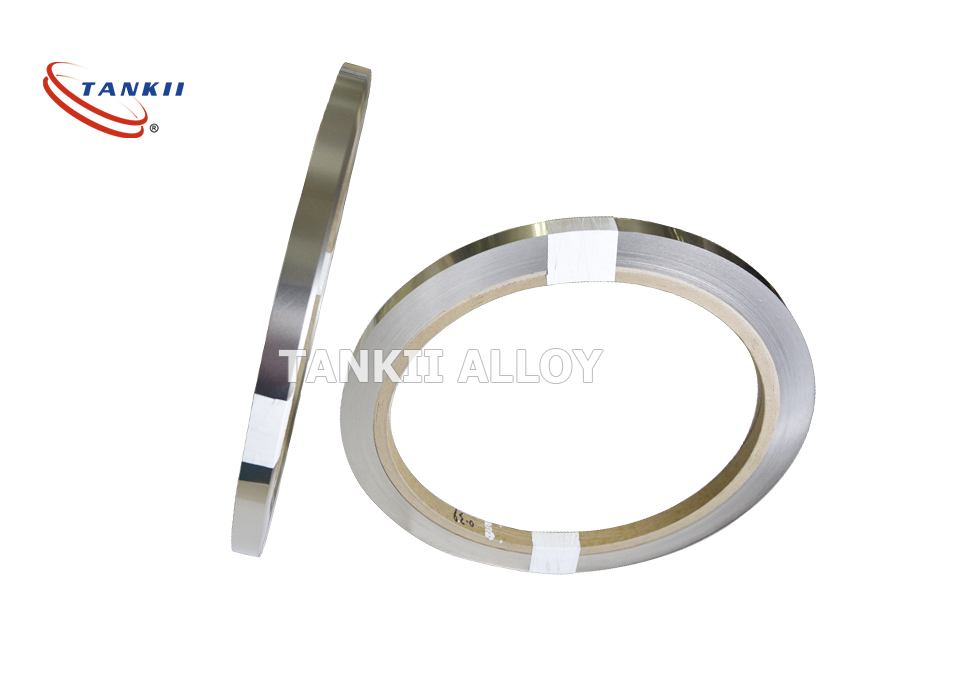

Xarig xarig ah oo ah 0.05mm Dhumucda FeCrAl

Daawaha FeCrAlDuubka Foornada/Xariiqda 0.05mm Dhumucda Substrate-ka Malab-ka Birta ah

Aluminium-ka oo sarreeya, oo ay weheliso chromium-ka sare, ayaa sababa in heerkulka cabbirku uu kordho ilaa 1425 C (2600F); Hoos waxaa ku qoran iska caabbinta kulaylka, kuwaasDaawaha FeCrAls waxaa la barbar dhigaa birta saldhiga Fe iyo Ni ee si caadi ah loo isticmaalo. Sida laga arki karo jadwalkaas,Daawaha FeCrAls waxay leeyihiin sifooyin ka sarreeya marka loo eego biraha kale ee ku jira inta badan deegaannada.

Waa in la ogaadaa, inta lagu jiro xaaladaha heerkulka ee isbeddelaya, ku darista yttrium ee daawaha AF kaas oo sidoo kale loo yaqaan daawaha Fecralloys, waxay wanaajisaa ku dhegganaanta oksaydhka ilaaliya, taasoo ka dhigaysa cimriga adeegga ee qaybaha daawaha AF mid ka dheer kan darajada A-1.

Fiilooyinka birta ah ee Fe-Cr-Al waxaa laga sameeyay birta birta ah ee chromium oo ka kooban xaddi yar oo walxo falgal ah sida yttrium iyo zirconium waxaana lagu soo saaraa dhalaalinta, duubista birta, sameynta, xoqidda, sawiridda, daaweynta dusha sare, tijaabada xakamaynta iska caabbinta, iwm.

Siligga Fe-Cr-Al waxaa lagu sameeyay mashiinka qaboojinta otomaatiga ah ee xawaaraha sare leh kaas oo awoodda korontada lagu xakameeyo kombiyuutar, waxaana laga heli karaa silig iyo xarig.

Sifooyinka iyo faa'iidooyinka

1. Heerkulka isticmaalka sare, heerkulka ugu badan ee la isticmaalo wuxuu gaari karaa 1400C (0Cr21A16Nb, 0Cr27A17Mo2, iwm.)

2. Isku-darka heerkulka hooseeya ee iska caabbinta

3. Isugeynta ballaarinta kulaylka oo ka hooseysa Ni-base super-alloys.

4. Iska caabin koronto oo sareysa

5. Iska caabin wanaagsan oo daxalka ah heerkulka sare, gaar ahaan jawiga ay ku jiraan sulfide-yada

6. Culays sare oo dusha sare ah

7. U adkaysta gurguurta

8. Qiimaha alaabta ceeriin oo hooseeya, Cufnaanta oo hooseysa iyo qiimo jaban marka la barbar dhigo siligga Nichrome.

9. Iska caabin oksaydh oo heer sare ah oo ah 800-1300ºC

10. Cimri dheer oo adeeg ah

Samaynta marxaladaha alumina ee la kala saari karo oo ay ugu wacan tahay oksaydhka ganacsigaDaawaha FeCrAlFiilooyinka (dhumucdoodu waa 0.5 mm) heerkul kala duwan iyo waqtiyo kala duwan ayaa la baaray. Muunadaha waxaa si gooni gooni ah loogu oksijiyey hawada iyadoo la adeegsanayo falanqeeye thermogravimetric (TGA). Qaab-dhismeedka muunadaha oksaydhka ah waxaa lagu falanqeeyay iyadoo la adeegsanayo Microscope Elektaroonik ah oo Iskaan ah (ESEM) iyo falanqaynta X-ray ee dusha sare waxaa lagu sameeyay iyadoo la adeegsanayo falanqeeye X-Ray (EDX) oo Energy Dispersive Energy. Farsamada Kala-soocidda X-Ray (XRD) ayaa loo isticmaalay in lagu qeexo wejiga koritaanka oksaydhka. Daraasadda oo dhan waxay muujisay inay suurtogal tahay in lagu koriyo alumina gamma oo dusha sare ah oo ku taalDaawaha FeCrAldusha sare ee siligga marka si iskeed ah oksaydh loogu daro heerkul ka sarreeya 800°C dhowr saacadood gudahood.

| Birta Chrome Aluminium | |||||||

| OCr25Al5 | CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Birta Chrome Aluminium | ||

| OCr25Al5 | Waxaa loo isticmaali karaa xaaladaha hawlgalka ilaa 1350°C, inkastoo uu noqon karo mid qaloocsan. | Walxaha kululaynta ee foornada heerkulka sare leh iyo kuleyliyeyaasha shucaaca leh. |

| OCr20Al5 | Daloolo ferromagnetic ah oo loo isticmaali karo heerkul ilaa 1300°C ah. Waa in lagu shaqeeyaa jawi qalalan si looga fogaado miridhku. Waxay noqon kartaa mid qaloocsan heerkul sare. | Walxaha kululaynta ee foornada heerkulka sare leh iyo kuleyliyeyaasha shucaaca leh. |

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare