Gariiradda Guga

pSharaxaadda badeecada

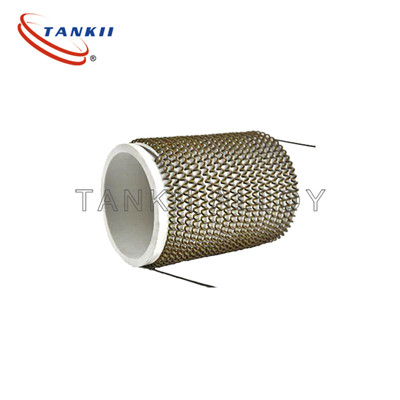

Shirkaddayadu waxay soo saartaa fiilooyin tayo sare leh oo bir-chromium-aluminium ah iyo nickel-chromium ah oo ku shaqeeya kuleylka korontada, kuwaas oo qaata awood koronto oo ku shaqeeya kombiyuutarka waxaana qaabeeya mashiin xawaare sare leh oo otomaatig ah. Astaamaha badeecadan: iska caabin heerkul sare, kuleyl degdeg ah, cimri dheer oo adeeg ah, iska caabin deggan, leexasho yar oo awood ah, isku dheelitirnaan siman ka dib fidinta, dusha sare oo dhalaalaya oo nadiif ah; si weyn loogu isticmaalo foornada yaryar ee korontada ku shaqeeya, foornada muffle, qalabka kuleylinta iyo qaboojiyaha, foornooyinka kala duwan, tuubooyinka kuleylinta korontada iyo qalabka guryaha, iwm. Baararka foornada warshadaha iyo kuwa madaniga ah ee aan caadiga ahayn ayaa la naqshadeyn karaa oo la soo saari karaa iyadoo loo eegayo baahiyaha isticmaalaha.

| Awood W | Voltage V | Dhexroorka mm | OD mm | LIngiriis (Tixraaca) mm | Wsiddeed g |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Heerkulka iyo halabuurka kiimikada ee fiilada kuleylinta

| Fasal | Ugu badnaan. Joogto ah Dabeecadda Hawlgalka. | Cr% | Ni% | Al% | Fe% | Dib-u-eegis% | Nb% | Bisha% |

| Cr20Ni80 | 1200℃ | 20~23 | Bal. |

|

|

|

|

|

| Cr30Ni70 | 1250℃ | 28~31 | Bal. |

|

|

|

|

|

| Cr15Ni60 | 1150℃ | 15~18 | 55~61 |

| Bal. |

|

|

|

| Cr20Ni35 | 1100℃ | 18~21 | 34~37 |

| Bal. |

|

|

|

| TANKII APM | 1425℃ | 20.5~23.5 |

| 5.8 | Bal. | / |

|

|

| 0Cr27Al7Mo2 | 1400℃ | 26.5~27.8 |

| 6~7 | Bal. |

|

| 2 |

| 0Cr21Al6Nb | 1350℃ | 21~23 |

| 5~7 | Bal. |

| 0.5 |

|

| 0Cr25Al5 | 1250℃ | 23~26 |

| 4.5~6.5 | Bal. |

|

|

|

| 0Cr23Al5Y | 1300℃ | 22.5~24.5 |

| 4.2~5.0 | Bal. |

|

|

|

| 0Cr19Al3 | 1100℃ | 18~21 |

| 3~4.2 | Bal. |

|

|

|

Sifooyinka farsamada ee ugu muhiimsan ee fiilada daawaha FeCrAl:

① Heerkulka isticmaalka waa mid sarreeya, heerkulka isticmaalka ee siligga aluminiumka birta-chromium ee jawiga wuxuu gaari karaa 1300℃;

②Cimri dheer oo adeeg ah;

③ Culayska dusha sare ee la oggol yahay waa weyn yahay;

⑤ Cuf-isjiidadka gaarka ah wuu ka yar yahay dahaarka nikkel-chromium; ④Is-caabbinta oksaydhku waa wanaagsan tahay, filimka AI2O3 ee la sameeyay ka dib oksaydhku wuxuu leeyahay iska caabin kiimiko oo wanaagsan iyo iska caabin sare;

⑥Is-caabin sare;

⑦Iska caabbinta sulfur ee wanaagsan;

⑧Qiimaha ayaa si weyn uga hooseeya kan dahaarka nikkel-chromium;

⑨Dhibaatadu waxay tahay marka heerkulku kordho, waxay muujisaa dabacsanaan, xoogguna heerkul sare wuu hooseeyaa.

Astaamaha fiilada shooladda korontada ee nickel-chromium waa:

① Xoog sare heerkulka sare;

② Qabooji ka dib isticmaalka muddada dheer, walaxdu ma noqon doonto mid jajaban;

③Isu-baxa daawaha Ni-ming ee si buuxda u oksaydhaysan ayaa ka sarreeya kan daawaha Fe-Cr-Al;

④Ma jiro birlab;

⑤Marka laga reebo jawiga baaruudka, waxay leedahay iska caabin daxalka oo ka wanaagsan

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare