Iska caabinta Korontada ee Wareega CuNi Alloy 1 - 5 Mohm oo loogu talagalay Qaybaha Kuleyliyaha Hawada

Iska caabinta Korontada ee Wareega ah Nicr Alloy 1 - 5 Mohm oo loogu talagalay Qaybaha Kuleyliyaha Hawada

1. Sharaxaadda Guud ee Agabka

Constantanwaa daawaha naxaasta-nickel oo sidoo kale loo yaqaanEureka,Horumarsan, iyoDoon. Badanaa waxay ka kooban tahay 55% naxaas iyo 45% nikkel. Astaamaheeda ugu weyn waa iska caabinteeda, taas oo joogto ah heerkul kala duwan. Daloolo kale oo leh isku-xidhka heerkulka hooseeya ayaa la yaqaan, sida manganin (Cu)86Mn12Ni2).

Cabbiraadda noocyada aadka u waaweyn, 5% (50 000 microstrian) ama ka sarreeya, constantan annealed (P alloy) ayaa ah walxaha shabagga ee sida caadiga ah loo doorto. Constantan qaabkan waa mid aad u wanaagsanductile; iyo, dhererka cabbirka ee 0.125 inji (3.2 mm) iyo ka dheer, waxaa lagu dhejin karaa >20%. Si kastaba ha ahaatee, waa in maskaxda lagu hayaa in marka la eego noocyada wareegga sare, daawaha P wuxuu muujin doonaa isbeddel iska caabin joogto ah wareeg kasta, wuxuuna sababi doonaa isbeddel u dhigmaeberIsbeddelka cabbirka cadaadiska. Sababtoo ah sifadan, iyo u janjeera cilladaha shabakadda ee dhicis ah iyadoo la isticmaalayo cadaadis soo noqnoqda, P alloy caadi ahaan laguma talinayo codsiyada cadaadiska wareega. P alloy waxaa laga heli karaa lambarrada STC ee 08 iyo 40 si loogu isticmaalo biraha iyo balaastikada, siday u kala horreeyaan.

2. Hordhaca Gu'ga iyo codsiyada

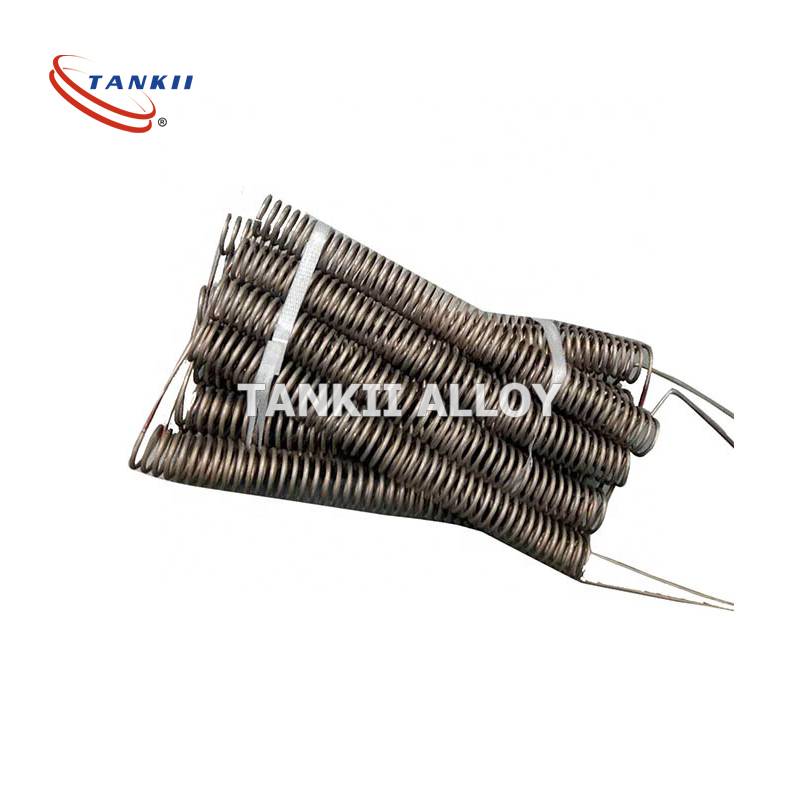

Guga wareegga ah ee wareegsan, ama gugga timaha, oo ku jira saacad qaylo-dhaan ah.

Gu' weyn. Marka la cadaadiyo, gariiradu way is dul simbiriirixanayaan, taasoo sahlaysa safar dheer.

Ilo toosan oo taangiga Stuart ah

Xiisadda ayaa ku jirta qalab dib-u-rogid xariiq laalaaban.

Bar torsion ah oo qalloocan oo culays saaran yahay

Guga caleenta ee gaadhi xamuul ah

Guluubyada waxaa loo kala saari karaa iyadoo ku xiran sida xoogga culayska loogu dabaqo:

Guga xiisadda/kordhinta - gu'ga waxaa loogu talagalay inuu ku shaqeeyo culays xiisad, sidaas darteed gu'gu wuu fidaa marka culayska lagu shubo.

Guga cadaadiska - waxaa loogu talagalay inuu ku shaqeeyo culays cadaadis, sidaas darteed gu'gu wuu gaabiyaa marka culayska lagu shubo.

Guga torsion - si ka duwan noocyada kor ku xusan ee culaysku yahay xoog axial ah, culayska lagu dabaqay guga torsion waa xoog torsion ah ama qalloocan, dhammaadka guguna wuxuu ku wareegaa xagal marka culayska la mariyo.

Guga joogtada ah - culayska la taageeray wuxuu ahaanayaa isku mid inta lagu jiro wareegga leexashada.

Guga isbeddelaya - iska caabbinta gariiradda si loo raro way kala duwan tahay inta lagu jiro cadaadiska.

Guga adkaanta isbeddelka leh - iska caabbinta gariiradda si loo raro waxaa si firfircoon u kala duwanaan kara tusaale ahaan nidaamka xakamaynta, noocyada qaar ee ilo-biyoodkan ayaa sidoo kale kala duwan dhererkooda taasoo siinaysa awood dhaqdhaqaaq sidoo kale.

Waxa kale oo loo kala saari karaa iyadoo lagu saleynayo qaabkooda:

Guga fidsan - noocan waxaa laga sameeyay bir guga fidsan.

Guga mashiinka lagu sameeyo - noocan guga waxaa lagu sameeyaa mashiinka baarka iyadoo la adeegsanayo mashiinka wax lagu shiido iyo/ama shaqada wax lagu shiido halkii laga isticmaali lahaa shaqada wax lagu shiido. Maadaama la farsameeyo, gugu wuxuu ku dari karaa astaamo marka lagu daro curiyaha laastikada ah. Guga mashiinka lagu sameeyo waxaa lagu samayn karaa kiisaska culeyska caadiga ah ee cadaadiska/kordhinta, leexashada, iwm.

Guga Serpentine - silig qaro weyn leh - oo badanaa loo isticmaalo dahaarka/alaabada casriga ah.

3. Halabuurka Kiimikada iyo Hantida ugu Muhiimsan ee Daawaha Cu-Ni ee Iska caabinta Yar

| Astaamaha Fasalka | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Halabuurka Kiimikada ugu Muhiimsan | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Heerkulka Adeegga Joogtada ah ee Ugu Badan (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Adkeysiga 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Cufnaanta (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Qaboojinta Kulaylka (α × 10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Xoogga Laabista (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Barta Dhalmada ee Qiyaas ahaan (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Qaab-dhismeedka Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | |

| Hantida Birlabta ah | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | |

| Astaamaha Fasalka | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Halabuurka Kiimikada ugu Muhiimsan | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Heerkulka Adeegga Joogtada ah ee Ugu Badan (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Adkeysiga 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Cufnaanta (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Qaboojinta Kulaylka (α × 10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Xoogga Laabista (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Barta Dhalmada ee Qiyaas ahaan (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Qaab-dhismeedka Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | |

| Hantida Birlabta ah | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | |

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare