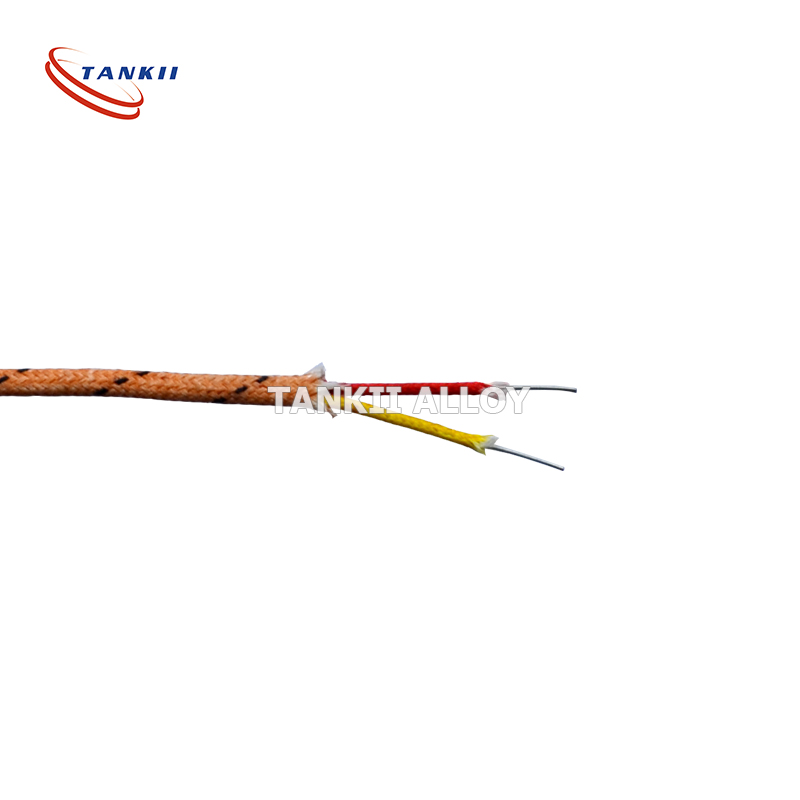

Xadhig Wareeg ah oo Polyester ah oo leh 0.1 Mm 430 oo aan lahayn Xarig loogu talagalay Iska caabbinta

Xarig Wareeg ah oo Polyester ah oo leh bir bir ah oo 0.1 Mm 430 ah oo aan lahayn birCaabiyes

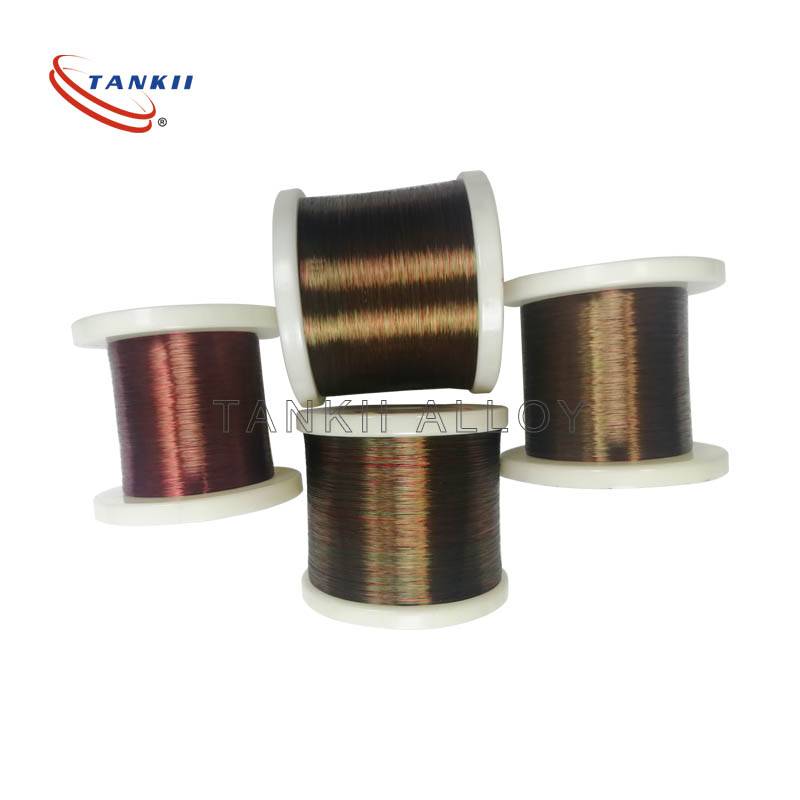

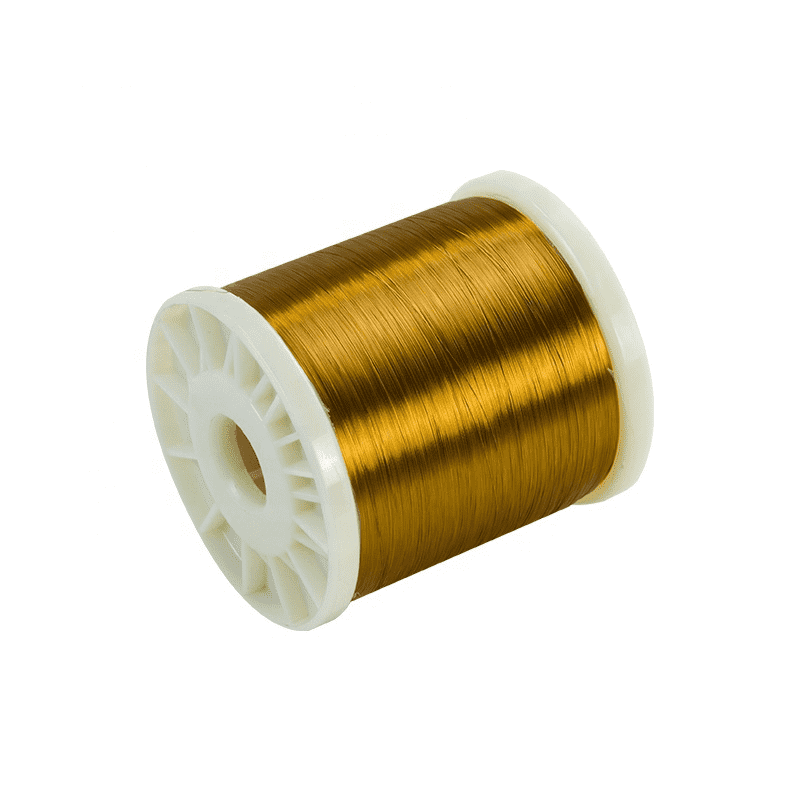

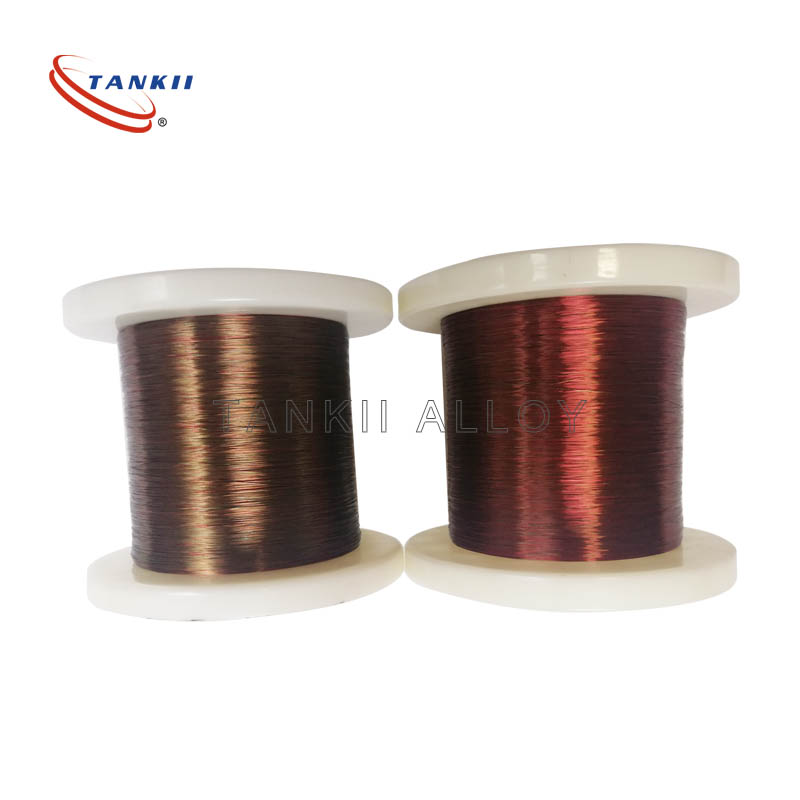

Fiilada birlabtaamasilig dhaldhalaal ahwaa silig naxaas ah ama aluminium ah oo lagu dahaadhay lakab aad u khafiif ah oo dahaadh ah. Waxaa loo isticmaalaa dhismaha transformers, inductors, matoorada, sameecadaha, actuators-ka madaxa adag, electromagnets, iyo codsiyada kale ee u baahan gariirado adag oo silig dahaaran.

Fiilada lafteeda badanaa waa naxaas si buuxda loo nuugay oo si elektaroonik ah loo safeeyey. Fiilada birlabta aluminiumka waxaa mararka qaarkood loo isticmaalaa transformers-ka waaweyn iyo matoorada. Dahaarka waxaa badanaa laga sameeyaa agab adag oo polymer ah halkii laga isticmaali lahaa dhaldhalaalka, sida magacu tilmaamayo.

Fiilooyinka la isku dhejiyay ayaa muhiim u ah isticmaalka gariiradda. Tusaale ahaan iska caabbinta kulaylka (heerkulka la jaray) ama cimri dhererka heerkulka ama astaamaha habaynta (lagu milmi karo) waa shuruudo muhiim ah.

Waxaa jira noocyo badan oo fiilooyin ah oo dhaldhalaal leh oo la heli karo. Dahaarka kala duwan waxaa lagu sharaxay heerar kala duwan, sida IEC 60 17, NEMA 60 317 ama JIS C 3202, kuwaas oo mararka qaar wali isticmaala habab tijaabo oo kala duwan.

Sida ku cad heerka (loo habeeyey gobolka meesha ku habboon), qiimaha farsamada ee caadiga ah waxaa la siiyaa dahaarka kala duwan, sida Polyurethane, Polyester, Polyesterimide, Polyimide, iwm.

Si loo fududeeyo isbarbardhigga badeecadaha iyo qiimeynta ku habboonaantooda codsiyada qaarkood waxaa ku yaal sanduuq calaamadeysan oo ka hooseeya mid kasta oo ka mid ah lambarrada badeecadaha iyo badhanka "Isbarbardhig Shayada La Xushay" ee ku yaal safka hore ee jadwalka. Marka badhankan la riixo, shayada la calaamadeeyay oo keliya ayaa harsan oo dhinac u soo muuqda. Aragtidan jadwalka ayaa sidoo kale ku habboon daabacaadda; fadlan isticmaal xulashooyinka biraawsarkaaga ujeeddadaas.

Isticmaalka badhanka "Muuji dhammaan" wuxuu ka dhigayaa alaabada aan la arki karin inay dib u soo muuqdaan mar kale.

Agabka ugu habboon ee loogu talagalay isticmaalka fiilooyinka birlabta waa biraha saafiga ah ee aan la isku darin, gaar ahaan naxaasta. Marka la tixgeliyo arrimaha sida kiimikada, fiisikiska, iyo shuruudaha hantida farsamada, naxaasta waxaa loo arkaa kontaroolaha doorashada koowaad ee fiilada birlabta.

Inta badan, fiilada birlabta waxay ka samaysan tahay naxaas si buuxda loo nuugay oo si elektaroonik ah loo safeeyey si loogu oggolaado in si dhow loo wareego marka la samaynayo gariiradaha elektaroonikka. Darajooyinka oksijiinta/naxaasta aan saafiga ahayn ee saafiga ah waxaa loo isticmaalaa codsiyada heerkulka sare ee lagu yareeyo jawiga ama matoorada ama matoorada ay qaboojiso gaaska haydarojiin.

Fiilada birlabta aluminiumka mararka qaarkood waxaa loo isticmaalaa beddel ahaan transformers-ka waaweyn iyo matoorada. Sababtoo ah kontoroolka korontada oo hooseeya, fiilka aluminiumku wuxuu u baahan yahay aag isgoys ah oo 1.6 jeer ka weyn kansilig naxaas ahsi loo gaaro iska caabin DC oo la mid ah.

| PEW | |

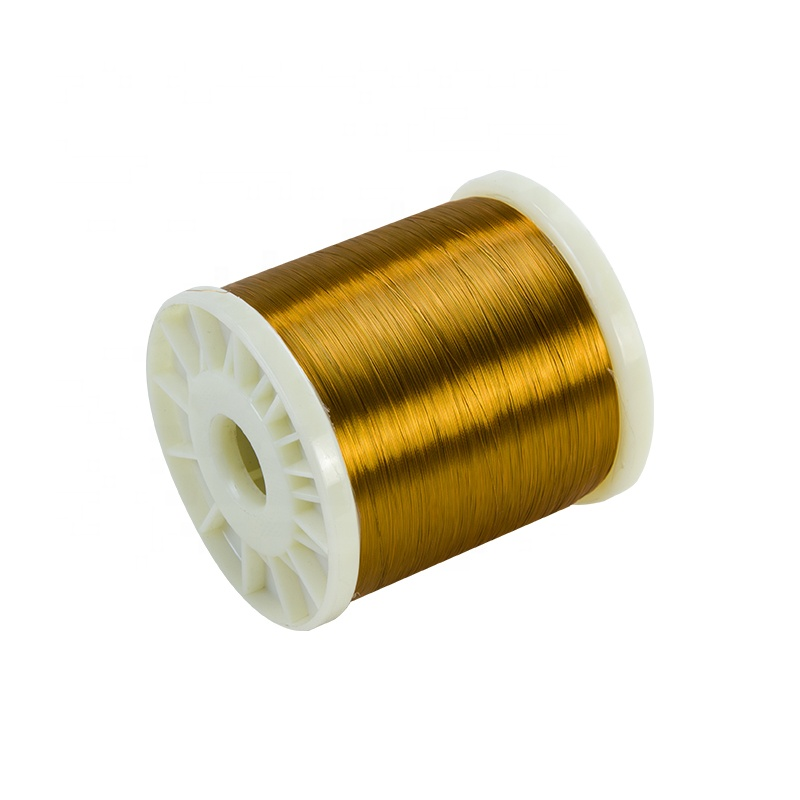

| Nooca | QZ-1-2/130L/155 |

| Dhexroorka | 0.50-2.50 |

| 0.40-0.49 | |

| 0.30-0.39 | |

| 0.20-0.29 | |

| 0.15-0.19 | |

| Kulayl | B 130 ºC F 155 ºC |

| Heerka Caadiga ah | GB/T6109.1-2008 GB/T6109.7-2008 (130L) GB/T6109.2-2008(155) |

| Codsiga | Taageere, qaboojiyaha hawada, qalabka korontada, mashiinka dharka lagu dhaqo, matoor yar, matoor qarax u adkaysta, balaastig, transformer nooca qalalan iyo wareegyo kale oo ku jira qalabka korontada. |

| Astaamaha | 1. Silig aad u fiican oo u adkaysta kulaylka 2. Iska caabin wanaagsan oo dareere ah 3. Xoogga farsamada oo leh (PVF)silig dhaldhalaal ahisku mid ah 4. waxqabadka korontada oo lehpolyestersilig naxaas ah oo wareegsan oo la dahaadhay 5. Jilicsanaanta iyo gabowga aadka u fiican |

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare