Ku soo dhawoow boggayaga internetka!

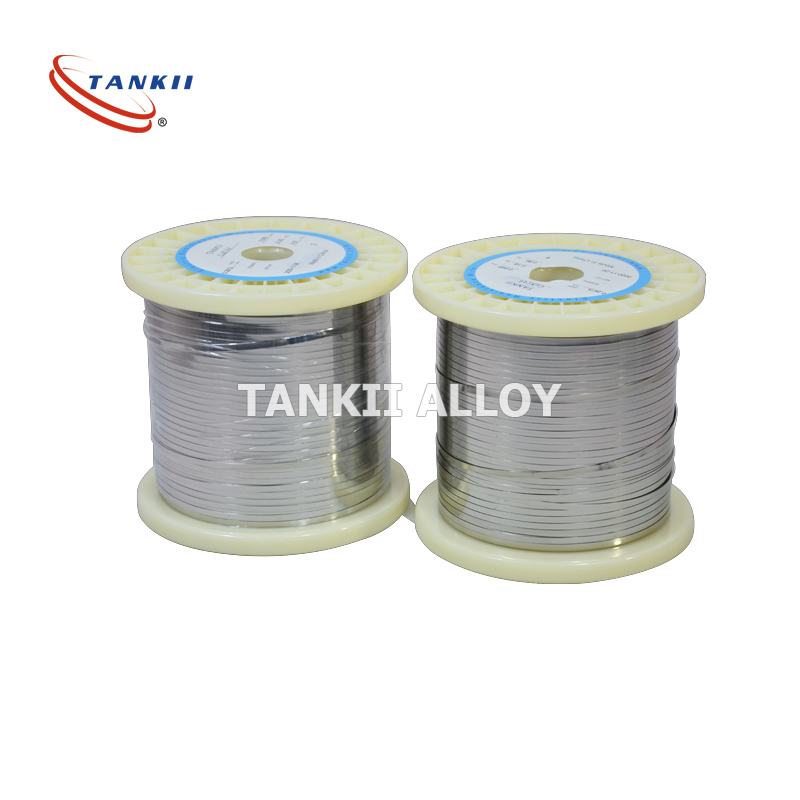

Sahayda Xirfadeed ee ASTM TM2 Bimetallic Ribbon, Waxqabad Xasilloon oo Lagu Kalsoonaan Karo

Sharaxaadda Badeecada

ASTMTM2Ribbo bimetal ahMagaca guud: Truflex P675R, Chace 7500, Telcon200, Kan 200)

ASTM TM2 oo ah nooca Bimetallic wuxuu leeyahay xasaasiyad kuleyl oo aad u sareysa iyo iska caabin sare, laakiin qaabka dabacsanaanta iyo cadaadiska la oggol yahay ayaa hooseeya, waxay hagaajin kartaa xasaasiyadda qalabka, yareyn kartaa cabbirka oo kordhin kartaa xoogga.

ASTM TM2 oo ah nooca Bimetallic wuxuu leeyahay xasaasiyad kuleyl oo aad u sareysa iyo iska caabin sare, laakiin qaabka dabacsanaanta iyo cadaadiska la oggol yahay ayaa hooseeya, waxay hagaajin kartaa xasaasiyadda qalabka, yareyn kartaa cabbirka oo kordhin kartaa xoogga.

Halabuurka

| Fasal | ASTM TM2 |

| Lakabka ballaarinta sare | Mn75Ni15Cu10 |

| Lakab ballaarin hoose | Ni36 |

Halabuurka kiimikada(%)

| Fasal | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Ni36 | ≤0.05 | ≤0.3 | ≤0.6 | ≤0.02 | ≤0.02 | 35~37 | - | - | Bal. |

| Fasal | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Mn72Ni10Cu18 | ≤0.05 | ≤0.5 | Bal. | ≤0.02 | ≤0.02 | 9~11 | - | 17~19 | ≤0.8 |

Sifooyinka Jirka ee Caadiga ah

| Cufnaanta (g/cm3) | 7.7 |

| Iska caabinta korontada ee 20ºC (ohm mm2/m) | 1.13 ±5% |

| Gudbinta kulaylka, λ/ W/(m*ºC) | 6 |

| Modulus Lalab ah, E/ Gpa | 113~142 |

| Laabista K / 10-6 ºC-1(20~135ºC) | 20.8 |

| Heerka foorarsiga heerkulka F/(20~130ºC)10-6ºC-1 | 39.0% ±5% |

| Heerkulka la oggol yahay (ºC) | -70~ 200 |

| Heerkulka toosan (ºC) | -20~ 150 |

Codsiga:Maaddada waxaa inta badan loo isticmaalaa sidii shaabad dhoobo ah oo aan magnetic ahayn oo aan la jaanqaadi karin oo ku taal Gyro iyo aaladaha kale ee faakuumka korontada ku shaqeeya.

Qaabka saadka

| Magaca Alloys | Nooca | Cabbirka | ||

| ASTM TM2 | Xarigga | W= 5~120mm | T= 0.1mm | |

Halkan ku qor fariintaada oo noo soo dir

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare