Ku soo dhawoow boggayaga internetka!

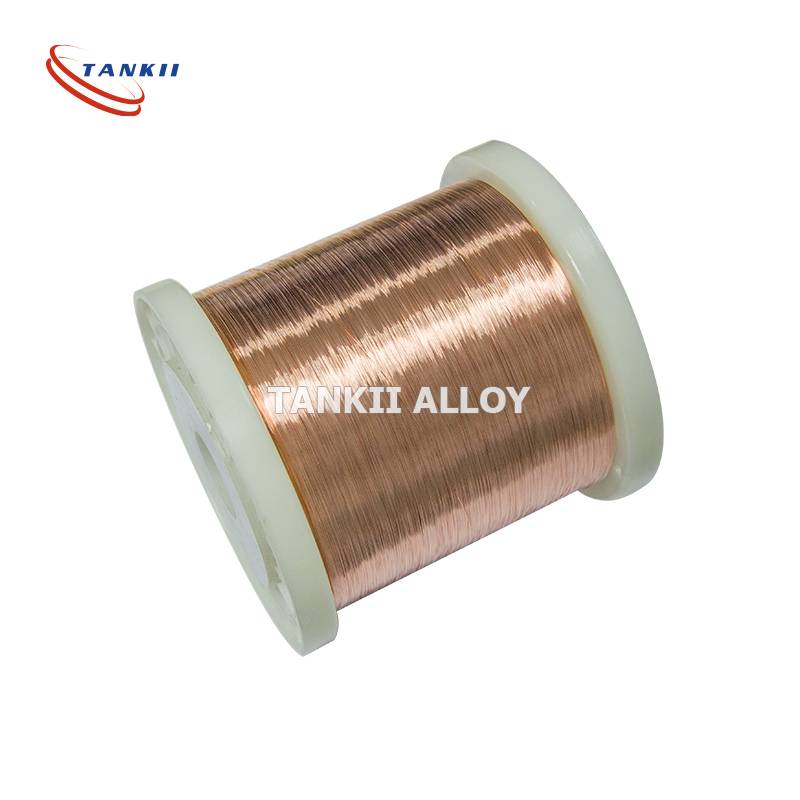

Ni80mo5 Permalloy 80 Mu 80 Silig jilicsan oo birlab ah

Faahfaahinta alaabtayada Ni80Mo5 ee soo socda waa kuwan:

Halabuurka kiimikada

| halabuurka | C | P | S | Mn | Si |

| ≤ | |||||

| Tusmada (%) | 0.03 | 0.02 | 0.02 | 0.3~0.6 | 0.15~0.3 |

| halabuurka | Ni | Cr | Mo | Cu | Fe |

| Tusmada (%) | 79.0~81.0 | - | 4.8~5.2 | ≤0.2 | Bal |

Nidaamka daaweynta kulaylka

| calaamadda dukaanka | Qalabka lagu buufiyo | heerkulka kululaynta | Heerkulka ilaali waqtiga/saacaddii | Heerka qaboojinta |

| 1j85 | Haydarojiin ama faakuum qalalan, cadaadisku kama weyna 0.1 Pa | Iyadoo la kululeynayo foornada ilaa 1100 ~ 1150ºC | 3~6 | Qaboojinta xawaaraha 100 ~ 200 ºC / saac ilaa 600 ºC, si dhakhso ah ilaa 300 ºC ayaa loo dallacayaa |

Difaaca magnetic-ka ee joogtada ah: Si looga hortago faragelinta goobta magnetic-ka ee dibadda, badanaa CRT, qaybta diiradda saareysa iftiinka elektaroonigga ah ee CRT oo lagu daray gaashaanka magnetic-ka, waxaad ciyaari kartaa doorka gaashaanka magnetic-ka.

Halkan ku qor fariintaada oo noo soo dir

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare