Ku soo dhawoow boggayaga internetka!

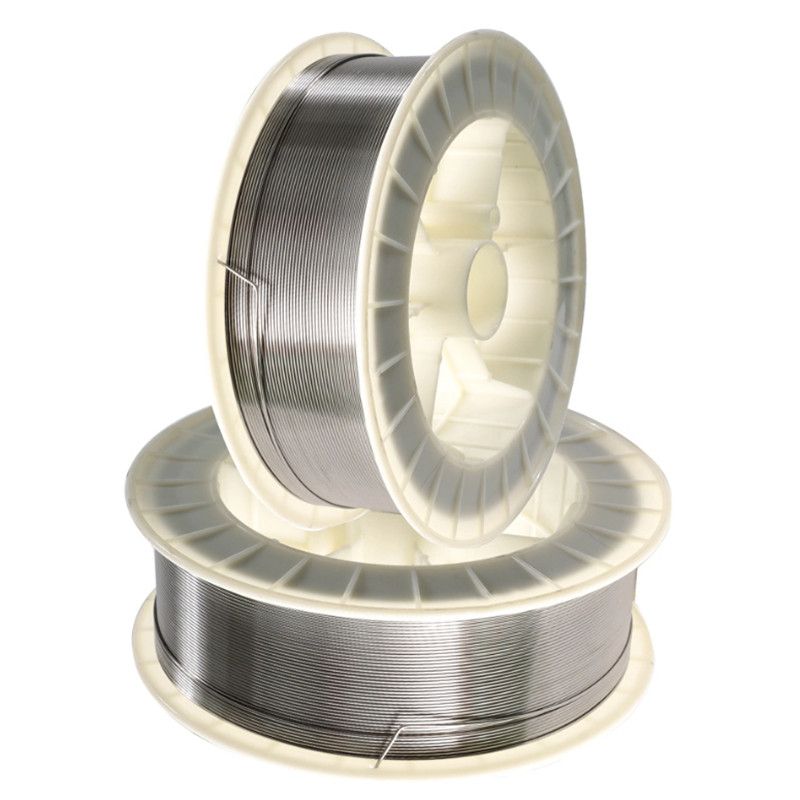

Iska caabinta Oksaydhaynta oo Wanaagsan 0.05MM NiCr 60 15 oo loogu talagalay Iska caabbinta Potentiometer

NiCr 60 15 (2.4867) waxaa loo isticmaalaa agabka kuleyliyaha korontada ee qalabka guryaha. Isticmaalka caadiga ah waa walxaha tuubooyinka birta ah ee dahaarka leh ee loo isticmaalo, tusaale ahaan, saxannada kulul, dubista, foornooyinka dubista dubista iyo kuleyliyeyaasha kaydinta. Daloolada 6015 waxaa sidoo kale loo isticmaalaa gariiradaha laalaada ee ku jira kuleyliyeyaasha hawada ee qalajiyaha dharka, kuleyliyeyaasha taageeraha, iyo qalajiyeyaasha gacanta.

- iska caabinta sare iyo kuwa potentiometer-ka.

- walxaha kuleyliyaha korontada (isticmaalka guriga iyo warshadaha).

- Foornooyinka warshadaha ilaa 1100°C.

| Fasal | Ni80Cr20 | Ni70Cr30 | Ni60Cr23 | Ni60Cr15 | Ni35Cr20 | Karma | Evanohm | |

| Halabuurka magacaaban% | Ni | Bal | Bal | 58.0-63.0 | 55.0-61.0 | 34.0-37.0 | Bal | Bal |

| Cr | 20.0-23.0 | 28.0-31.0 | 21.0-25.0 | 15.0-18.0 | 18.0-21.0 | 19.0-21.5 | 19.0-21.5 | |

| Fe | ≦1.0 | ≦1.0 | Bal | Bal | Bal | 2.0-3.0 | - | |

| Al1.0-1.7 Ti 0.3-0.5 | Al2.7-3.2 Mn0.5-1.5 | Al2.7-3.2 Cu2.0-3.0 Mn0.5-1.5 | ||||||

| Heerkulka ugu badan ee hawlgalka (°C) | 1200 | 1250 | 1150 | 1150 | 1100 | 300 | 400 | |

| Adkeysiga (Ω/cmf, 20℃) | 1.09 | 1.18 | 1.21 | 1.11 | 1.04 | 1.33 | 1.33 | |

| Adkeysiga (uΩ/m, 60°F) | 655 | 704 | 727 | 668 | 626 | 800 | 800 | |

| Cufnaanta (g/cm³) | 8.4 | 8.1 | 8.4 | 8.2 | 7.9 | 8.1 | 8.1 | |

| Qaboojinta Kulaylka (KJ/m·h·℃) | 60.3 | 45.2 | 45.2 | 45.2 | 43.8 | 46.0 | 46.0 | |

| Isugeynta Ballaarinta Toosan(×10¯6/℃) 20-1000℃) | 18.0 | 17.0 | 17.0 | 17.0 | 19.0 | - | - | |

| Barta Dhalmada (℃) | 1400 | 1380 | 1370 | 1390 | 1390 | 1400 | 1400 | |

| Adkaanta (Hv) | 180 | 185 | 185 | 180 | 180 | 180 | 180 | |

| Xoog Laab Laab (N/mm)2 ) | 750 | 875 | 800 | 750 | 750 | 780 | 780 | |

| Kordhinta (%) | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | 10-20 | 10-20 | |

| Qaab-dhismeedka Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | austenit | |

| Hantida Magnetic-ga | Aan ahayn | Aan ahayn | Aan ahayn | Si yar | Aan ahayn | Aan ahayn | Aan ahayn | |

| Nolosha Degdegga ah (h/℃) | ≥81/1200 | ≥50/1250 | ≥81/1200 | ≥81/1200 | ≥81/1200 | - | - | |

Halkan ku qor fariintaada oo noo soo dir

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare