FENi52/Nilo 52/Feni52/Alloy 52/ASTM F30 silig xariijin ah oo loogu talagalay beddelayaasha Reed Magnetic

Nife52/Nilo 52/Feni52/Alloy 52/ASTM F30 strips oo loogu talagalay furayaasha birta birta ah

Alloy 52 waxa uu ka kooban yahay 52% nikkel iyo 48% bir waxana si balaadhan looga isticmaalaa warshadaha isgaadhsiinta.Waxa kale oo ay ka helaysaa codsi noocyo kala duwan oo elektaroonik ah,gaar ahaan shaabadihii muraayadaha.

Alloy 52 waa mid ka mid ah muraayadda ilaa birta daabadaha ee loogu talagalay in lagu isticmaalo muraayadaha jilicsan ee kala duwan. Loo yaqaan isku-dhafka balaadhinta kulaylka oo ku dhawaad joogto ah ilaa 1050F (565 C).

Baaxadda Baaxadda:

*Xaasha- Dhumucdiisuna waa 0.1mm ~ 40.0mm, ballac:≤300mm, Xaaladda: qabow duuban (kulul), dhalaalaya, dhalaalaya annealed

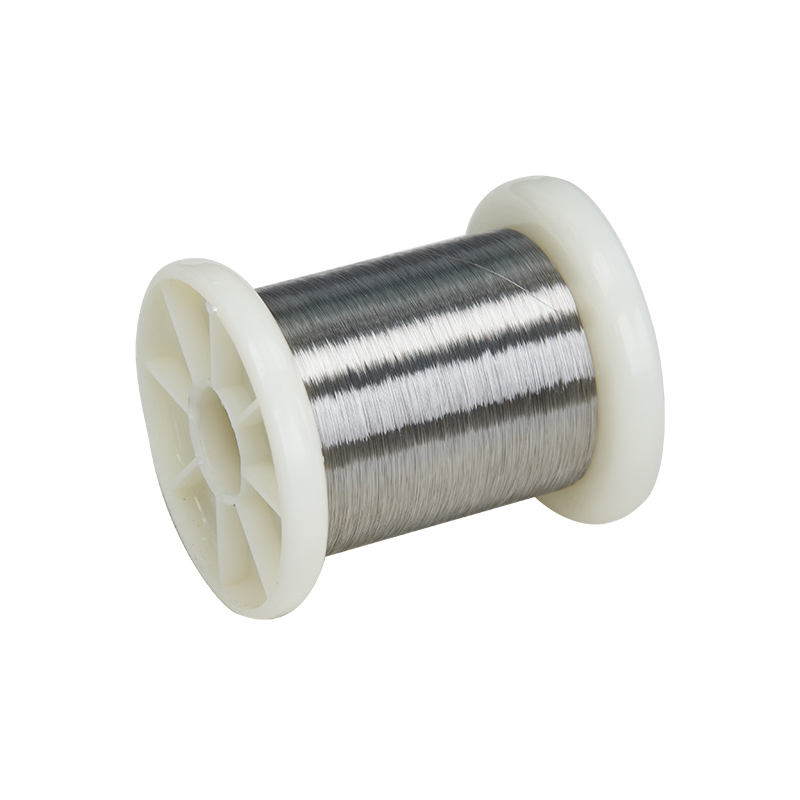

*Silig wareeg ah-Dia 0.1mm ~ Dia 5.0mm, Xaalad: qabow sawiran, dhalaalaya, dhalaalaya annealed

* Silig siman-Dia 0.5mm ~ Dia 5.0mm, dherer:≤1000mm, Xaaladda: fidsan giringiriyey, annealed dhalaalaya

*Bar-Dia 5.0mm ~ Dia 8.0mm, dhererka:≤2000mm, Xaalad: qabow sawiran, dhalaalaya, dhalaal la annealed

Dia 8.0mm ~ Dia 32.0mm, dhererka:≤2500mm, Xaaladda: kulul duuban, dhalaalaya, annealed dhalaalaya

Dia 32.0mm ~ Dia 180.0mm, dhererka: ≤1300mm, Xaaladda: foornada kulul, diiray, leexatay, daweeyay kulul

*Capillary-OD 8.0mm ~ 1.0mm, ID 0.1mm ~ 8.0mm, dhererka:≤2500mm, Xaaladda: qabow sawiran, dhalaalaya, dhalaalaya annealed.

* Dhuumaha-OD 120mm ~ 8.0mm,ID 8.0mm ~ 129mm, dhererka:≤4000mm, Xaaladda: qabow sawiran, dhalaalaya, dhalaalaya annealed.

Kiimikada:

| Cr | Al | C | Fe | Mn | Si | P | S | Ni | Mg | |

| Min | - | - | - | - | - | - | - | - | 50.5 | - |

| Max | 0.25 | 0.10 | 0.05 | Bal. | 0.60 | 0.30 | 0.025 | 0.025 | - | 0.5 |

Celceliska Iskuxidhka Balaadhinta Tooska ah:

| Darajo | α1/10-6ºC-1 | |||||||

| 20 ~ 100ºC | 20 ~ 200ºC | 20 ~ 300ºC | 20 ~ 350ºC | 20 ~ 400ºC | 20 ~ 450ºC | 20 ~ 500ºC | 20 ~ 600ºC | |

| 4J52 | 10.3 | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.3 | 10.8 |

Guryaha:

| Xaalad | Qiyaastii xoog adkaysi | Qiyaastii heerkulka shaqada | ||

| N/mm² | ksi | °C | °F | |

| La xiray | 450 - 550 | 65 - 80 | ilaa +450 | ilaa +840 |

| Adag La sawiray | 700 - 900 | 102 - 131 | ilaa +450 | ilaa +840 |

| Samaynta: |

| Daawadu waxay leedahay ductility wanaagsan waxaana lagu samayn karaa hab caadi ah. |

| alxanka: |

| Alxanka hababka caadiga ah ayaa ku habboon daawahaan. |

| Daawaynta Kulaylka: |

| Alloy 52 waa in lagu tirtiraa 1500F oo ay ku xigto qaboojin. Cadaadiska dhexdhexaadka ah ayaa lagu samayn karaa 1000F. |

| Been abuurasho: |

| Beeynta waa in lagu sameeyaa heerkul ah 2150 F. |

| Shaqada Qabow: |

| Daawaha si diyaar ah ayaa loo shaqeeyay. Darajada sawiridda qoto dheer waa in lagu qeexaa hawlgalka samaynta iyo darajada la tirtiray ee samaynta guud. |

Qaybaha alaabta

-

Taleefanka

-

E-mailka

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare