FeCrAl FeCr23Al5 A1 APM AF D Silig koronto oo u adkaysta kulaylka daawaha

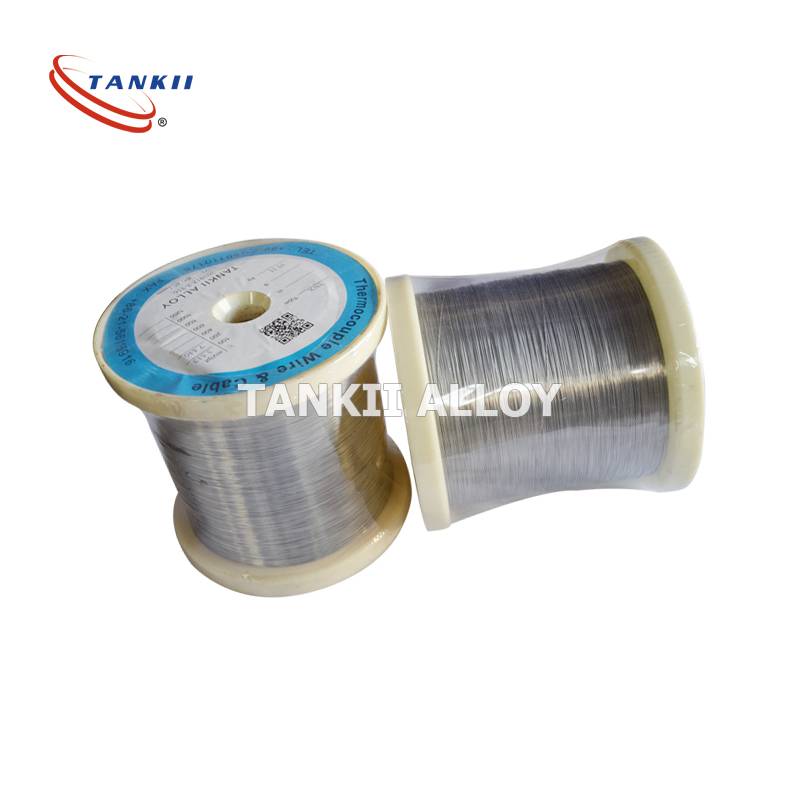

FeCrAl A1 APM AF D Fiilo koronto oo u adkaysta kulaylka daawaha

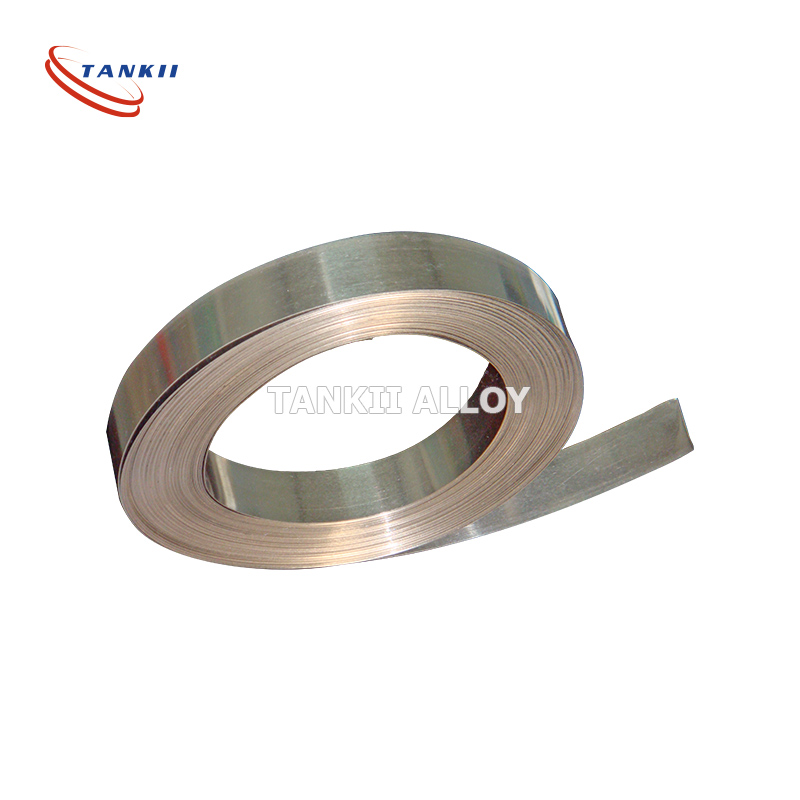

Ku saabsan Fiilada Kululaynta Iska caabinta:

Waxaan nahay soo saaraha xirfadleyda ugu weyn ee ka shaqeeya isku-darka kuleylka iska caabbinta ee Shiinaha, annagoo ku takhasusay siligga Ferro-Chrome (Fe-Cr-AL), siligga Nickel-Chrome (Nichrome), siligga Copper Nickel (Constantan), siligga birta aan miridhku lahayn iyo alaabada la xiriirta ee ku jira biraha loogu talagalay inay buuxiyaan shuruudaha macaamiisha gaarka ah.

Faahfaahinta cabbirka

| Magaca alaabta | Cabbirka baaxadda |

| Silig sawir qabow | Dhexroorka 0.03-7.5mm |

| Usha siligga kulul ee duuban | Dhexroorka 8.0-12mm |

| Ribbon | Dhumucda 0.05-0.35mm |

| Ballaca 0.5.0-3.5mm | |

| Xariijimo qabow oo la duubay | Dhumucda 0.5-2.5mm |

| Ballaca 5.0-40mm | |

| Xariijimo kulul oo la duubay | Dhumucda 4-6mm |

| Ballaca 15-40mm |

xuduudaha aasaasiga ah:

| xuduudaha aasaasiga ah | APMTM | FeCrAl | ||

| A-1 | AF | D | ||

| Heerkulka shaqada ee joogtada ah ee ugu sarreeya | 1425 | 1400 | 1300 | 1300 |

| Halabuurka kiimikada ee magacaaban,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | maaddooyinka | maaddooyinka | maaddooyinka | maaddooyinka |

| Ni | - | - | - | - |

| Iska caabinta 20ºC, Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| cufnaanta, g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| Isugeynta ballaarinta kulaylka K-1 20-750ºC | 14 × 10-6 | 14 × 10-6 | 14 × 10-6 | 14 × 10-6 |

| 20-1000ºC | 15 × 10-6 | 15 × 10-6 | 15 × 10-6 | 15 × 10-6 |

| Kobcinta kulaylka 20ºC, Wm-1K-1 | 13 | 13 | 13 | 13 |

| Awood kuleyl gaar ah 20ºC, KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Barta dhalaalaysa°C | 1500 | 1500 | 1500 | 1500 |

| Astaamaha farsamada ee suurtogalka ah | ||||

| Xoogga jiidista, N mm-2 | 680 | 680 | 680 | 650 |

| Xoogga wax-soo-saarka, N mm-2 | 470 | 475 | 475 | 450 |

| Adkaanta, Hv | 230 | 230 | 230 | 230 |

| Kordhinta jajaban,% | 20 | 18 | 18 | 18 |

| Xoogga ba'an ee 900ºCT, N mm-2 | 40 | 34 | 37 | 34 |

| Xoogga gurguurta 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Magnetic | birlab ah (Heerkulka 600ºC) | |||

| Iftiiminta, xaaladaha oksaydhka | 0.7 | 0.7 | 0.7 | 0.7 |

Faahfaahinta:

| Nooca Daawaha | Dhexroorka | Iska caabin | Gariir | Kordhinta (%) | Laablaabid | Ugu badnaan. Joogto ah | Nolosha Shaqada |

| (mm) | (μΩm) (20°C) | Xoog | Waqtiyada | Adeegga | (saacadaha) | ||

| (N/mm²) | Heerkulka (°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Faa'iidada:

Daawaha Nickelchromium oo leh iska caabin sare oo deggan, iska caabin daxalka, iska caabin oksaydh dusha sare ah ayaa wanaagsan, heerkul sare iyo xoog dhul gariir ah oo ka wanaagsan, ductility wanaagsan, shaqeyn wanaagsan iyo alxan.

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare