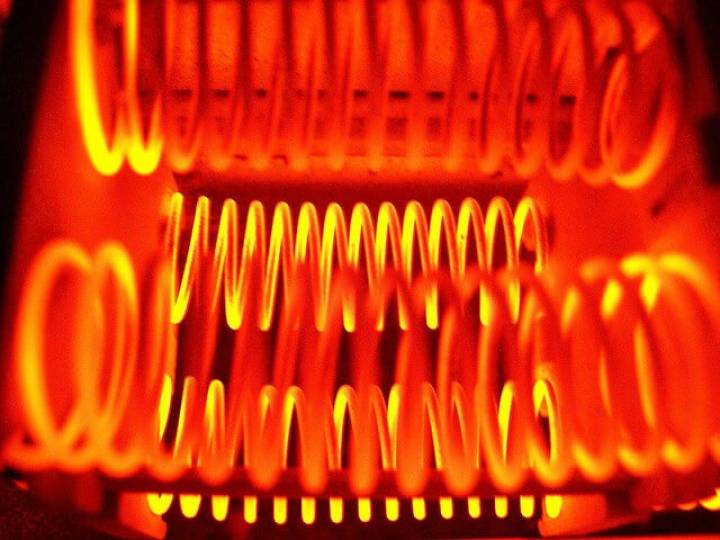

FeCrAl 0Cr25Al5 silig kuleyliye koronto ah oo kuleyliya

Hantida ugu Muhiimsan ee fiilada iska caabbinta kuleylka

| Nooca Daawaha | Dhexroorka (mm) | Iska caabin (μΩm) (20°C) | Gariir Xoog (N/mm²) | Kordhinta (%) | Laablaabid Waqtiyada | Ugu badnaan. Joogto ah Adeegga Heerkulka (°C) | Nolosha Shaqada (saacadaha) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| MAGACA | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Kiimikada WEYN | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| QAYBTA | Re | fursad | fursad | fursad | fursad | fursad | fursad | fursad |

| Fe | Nasasho | Nasasho | Nasasho | Nasasho | Nasasho | Nasasho | Nasasho | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Heerkulka ugu Sareeya (oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Iska caabin 20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Cufnaanta (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| ISBEDDELKA KULEYLKA | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| QIIMAHA (KJ/m·h·oC) | ||||||||

| Heerka ballaarinta (α × 10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| barta dhalaalka (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Xoogga jiidista (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| dheereyn (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| kala duwanaanshaha aagga (%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| soo noqnoqoshada laabashada (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| adkaansho (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| qaab-dhismeedka mikrografiga | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| hantida birlabta ah | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

| Dhexroor (mm) | Dulqaadka (mm) | Dhexroor (mm) | Dulqaadka (mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ±0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ±0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0.05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ±0.4 |

| Dhumuc (mm) | Dulqaadka (mm) | Ballaca (mm) | Dulqaadka (mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ±0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ±0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ±0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ±0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ±0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ±0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ±0.6 |

Waxaan nahay soo saaraha fiilada iska caabbinta kulaylka waxaa ka mid ah

Siliga FeCrAL, siliga NiCr, siliga CuNi:

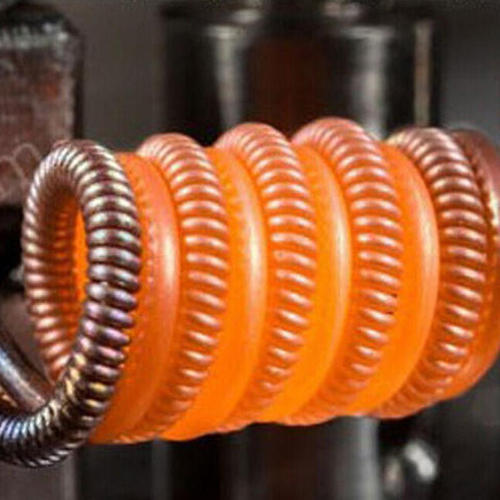

II Faa'iidada ugu Weyn iyo Codsiga

A. Halbeegga jireed:

1) Dhexroorka silig: 0.025 ~ 15mm

2) Nikkel saafi ah wuxuu leeyahay awood uu ugu adkeysto heerkulka sare isagoon xumaan.

heerkulku waa qiyaastii 600°C

3) Fiilada nikkel-ka waxaa laga heli karaa qaab-dhismeed hal-xadhig ah ama qaab-dhismeed badan. Waxaa laga keenayaa kaydka midkood qaawan yahay, ama dahaaran yahay.

B. Astaamaha:

1) Toosanaan aad u fiican

2) Dusha sare oo isku mid ah oo qurux badan oo aan lahayn dhibco

3) Awood aad u fiican oo sameynta gariiradda ah

C. Codsiyada ugu muhiimsan iyo ujeeddada guud:

1) Siliggan waxaa sidoo kale si ballaaran loogu isticmaali karaa guud ahaan daboolka transistor-ka, anodes-ka tuubooyinka elektaroonigga ah,

Fiilooyinka qaybaha elektaroonigga ah / fiilooyinka rasaasta ee laambadaha iyo shabagga siligga. Waxa kale oo loo isticmaalaa qaab xariijimo ah oo loogu talagalay noocyo kala duwan

codsiyada oo ay ku jiraan baytariyada Ni-Cd

2) Waxaa sidoo kale loo isticmaalaa fiilooyinka, Fiilada Lead-in-Siligga ee laambadaha, taageerada tuubooyinka elektaroonigga ah, maro silig ah oo loogu talagalay fiilooyinka isku xira korontada

halkaasoo heerkulku ka badan yahay kuwa naxaasta ku habboon, tolida siligga

3) Codsiyada caadiga ah waxaa ka mid ah: joojinta walxaha kululaynta sida foornada, qalabka balaastikada lagu shido, foornada.

Taageerada fiilooyinka iyo fiilooyinka rasaasta ee warshadaha iftiinka

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare