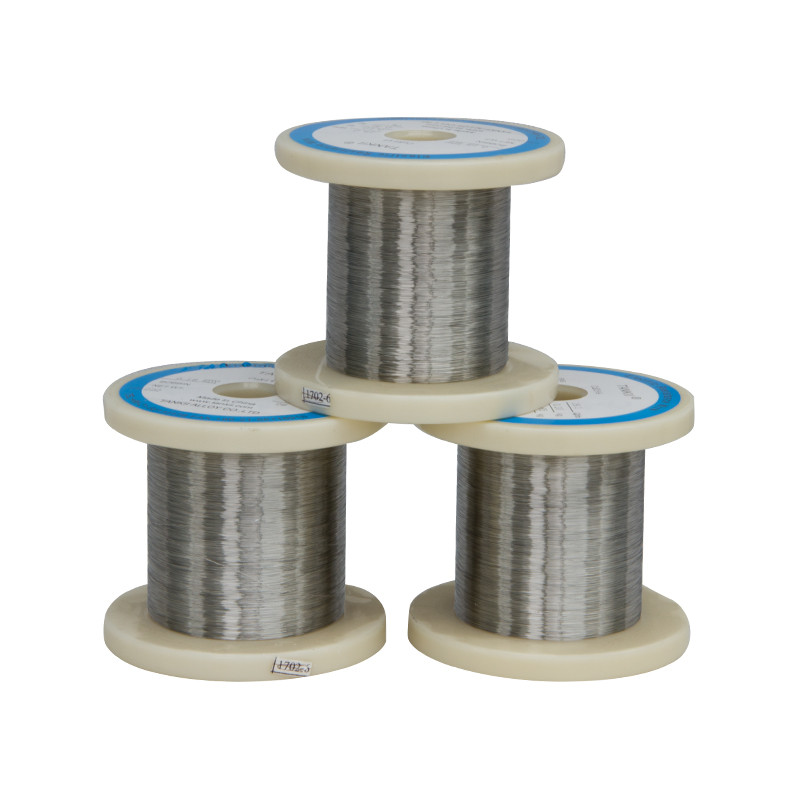

Qiimaha Warshadda Permalloy 1j85/1j79 1j50 Ni50 1j46 Ni46 Uns 45-Permalloy Silig Jilicsan oo Magnetic ah

Inta badan waxaa loo isticmaalaa laba qaybood oo loogu talagalay beddelka tamarta iyo habaynta macluumaadka

Warshadaha korontada, inta badan goobta birlabta sare waxay leedahay soo-saar birlab sare iyo lumis hoose oo ka timaadda birta. Warshadaha elektaroonigga, inta badan birta yar ama dhexdhexaadka ah waxay leedahay awood birlab sare iyo awood qasab oo hooseeya. Marka ay timaado hirarka sare waa in lagu sameeyaa xarig khafiif ah ama birlab leh iska caabin sare. Badanaa iyadoo la adeegsanayo xaashi ama xarig.

Alaabada jilicsan ee birlabta ah ee lagu beddelayo isticmaalka, sababtoo ah hirarka birlabta ee beddelka ah ayaa lagu kiciyaa gudaha maaddada, taasoo keenta luminta, iska caabbinta birta oo yar, dhumucduna way sii weynaanaysaa, soo noqnoqoshada goobta birlabta ee beddelka ah ayaa sii kordheysa, khasaaraha hadda ee eddy ayaa sii badanaya, magnetic-gu wuu sii yaraanayaa. Tan awgeed, walaxda waa in laga sameeyaa xaashi khafiif ah (cajalad), oo dusha sarena lagu dahaadhaa lakab dahaadh ah, ama isticmaalka habab gaar ah oo dusha sare ah si loo sameeyo lakab dahaadh ah oo oksaydh ah, dahaadhyada noocan oo kale ah waxaa badanaa loo isticmaalaa dahaarka electrophoresis ee magnesium oxide.

Daawaha birta-nickel inta badan waxaa loo isticmaalaa beddelka goobta magnetic, inta badan birta harqood, relay, Transformers-ka Awoodda Yar iyo kuwa Magnetic ahaan loo ilaaliyo.

Kuwa soo socda waa faahfaahinta alaabtayada 1J80:

Halabuurka kiimikada

| halabuurka | C | P | S | Mn | Si |

| ≤ | |||||

| Tusmada (%) | 0.03 | 0.020 | 0.020 | 0.60~1.10 | 1.10~1.50 |

| halabuurka | Ni | Cr | Mo | Cu | Fe |

| Tusmada (%) | 79.0~81.5 | 2.60~3.00 | - | ≤0.2 | Bal |

Nidaamka daaweynta kulaylka

| calaamadda dukaanka | Qalabka lagu buufiyo | heerkulka kululaynta | Heerkulka ilaali waqtiga/saacaddii | Heerka qaboojinta |

| 1j80 | Haydarojiin ama faakuum qalalan, cadaadisku kama weyna 0.1 Pa | Iyadoo la kululeynayo foornada ilaa 1100 ~ 1150ºC | 3~6 | Qaboojinta xawaaraha 100 ~ 200 ºC / saac ilaa 400 ~ 500 ºC, si dhakhso leh ilaa 200 ºC ayaa loo dallacayaa |

1J06,1J12,1J17,1J18,1J22,1J30,1J36,1J38,1J46,1J50,1J51,1J54,1J76,1J77,1J79,1J80,1J85,1J87

Daawaha magnetka joogtada ahMa aha oo kaliya inay leedahay adkeysi sare iyo sifooyin farsamo, laakiin sidoo kale waxay leedahay awood xooggan oo ka hortagga burburka, qiime xoog badan (ka weyn 20kA/m), "adag" birlab ah iyo astaamo kale, sidaa darteed waxaa sidoo kale loo yaqaan daawaha birlab adag.2J04,2J07,2J09,2J10,2J31,2J53,2J84,2J85 Daloolada laastikada ahwaxaa ku jira biraha laastikada sare leh iyo biraha laastikada joogtada ah. Waxaa loo isticmaalaa in lagu sameeyo biraha laastikada sida biraha xasaasiga ah, biraha kaydinta tamarta iyo biraha soo noqnoqda ee qalabka saxda ah.3J01,3J21,3J53

Daloolada laastikada ahwaxaa ku jira biraha laastikada sare leh iyo biraha laastikada joogtada ah. Waxaa loo isticmaalaa in lagu sameeyo biraha laastikada sida biraha xasaasiga ah, biraha kaydinta tamarta iyo biraha soo noqnoqda ee qalabka saxda ah.3J01,3J21,3J53

Daloolada ballaarinta (Daloolada Invar)Waxaa loo qaybiyaa birta Kovar, birta shaabadaysan ee dhoobada ah, birta ballaarinta hoose, iyo birta ballaarinta joogtada ah. Si ballaaran ayaa loogu isticmaalaa warshadaha elektaroonigga ah, qalabka cabbiraadda saxda ah, qalabka saxda ah iyo injineernimada heerkulka hooseeya iyo qaybaha kale..

4J28,4J29,4J32,4J33,4J36,4J40,4J42,4J50

Daloolada saxda ah ee leh nikkel, chromium, aluminium iyo bir oo ah qaybaha ugu muhiimsan, iska caabintu waxay qiyaastii saddex jeer ka sarreysaa tan naxaasta manganese, waxayna leedahay isku-darka heerkulka hooseeya ee iska caabinta iyo awoodda kulaylka oo hooseysa ee naxaasta, oo leh xasillooni iyo iska caabin muddo dheer ah oo wanaagsan. Sifooyinka oksaydhaynta.

Waxay ku habboon tahay sameynta walxaha iska caabbinta saxda ah ee qalabka cabbiraadda iyo mitirrada kala duwan, iyadoo la samaynayo walxaha iska caabbinta yar yar ee saxda ah iyo cabbirrada cadaadiska.

6J10,6J15,6J20,6J22,6J23,6J24

| daawaha ballaarinta | ||||||||||

| Fasal | C≤ | S≤ | P≤ | Mn | Si | Ni | Cr | Cu | Al | Fe |

| 6J10 | ≤0.05 | ≤0.01 | ≤0.01 | ≤0.3 | ≤0.2 | nI+cO rem | 9-10 | ≤0.2 | ≤0.4 | |

| 6J15 | ≤0.05 | ≤0.02 | ≤0.03 | ≤1.5 | 0.4-1.3 | 55-61 | 15-18 | ≤0.3 | rem | |

| 6J20 | ≤0.05 | ≤0.01 | ≤0.01 | ≤0.7 | 0.4-1.3 | rem | 20-23 | ≤0.3 | ≥1.5 | |

| 6J22 | ≤0.04 | ≤0.01 | ≤0.01 | 0.5-1.5 | ≤0.2 | rem | 19-21.5 | 2.7-3.2 | 2-3 | |

| 6J23 | ≤0.04 | ≤0.01 | ≤0.01 | 0.5-1.5 | ≤0.2 | rem | 19-21.5 | 2-3 | 2.7-3.2 | |

| 6J24 | ≤0.04 | ≤0.01 | ≤0.01 | 1.0-3.0 | 0.9-1.5 | rem | 19-21.5 | 2.7-3.2 | ≤0.5 | |

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare