Ku soo dhawoow mareegahayaga!

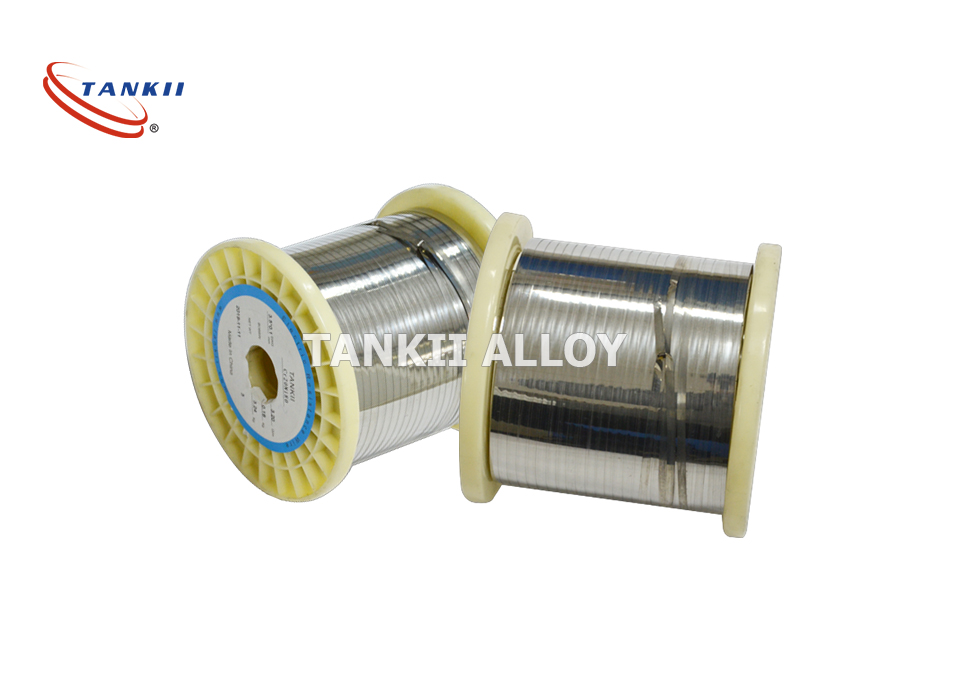

CuNi2/CuNi6/CuNi8/CuNi10/CuNi14

Siliggayaga Copper Nickel Alloy Wire waa walxo koronto oo tayo sare leh oo bixisa iska caabin koronto oo hooseeya, iska caabin kulayl aad u fiican, iyo iska caabin daxalka. Way sahlan tahay in la farsameeyo oo lagu hoggaamiyo alxanka, taasoo ka dhigaysa mid ku habboon codsiyada kala duwan ee warshadaha korontada. Caadi ahaan loo isticmaalo soo saarista qaybaha muhiimka ah ee relaysyada kulaylka badan, iska caabbinta hoose ee wareegga kulaylka, iyo qalabka korontada, our Copper Nickel Alloy Wire waa doorasho la isku halayn karo. Waxa kale oo si weyn loogu isticmaalaa fiilooyinka kuleylka korantada, taas oo ka dhigaysa shay lagama maarmaan u ah hababka kuleylka. Astaamaha Muhiimka ah:

Iska caabin koronto oo hooseeya

Iska caabbinta kulaylka wanaagsan

Iska caabbinta daxalka

Si fudud loo farsameeyo oo loo alxanayo Codsiyada:

Xakamaynta wareegga korantada hooseeya

Isku-gudbinta kulaylka badan

Xadhkaha kuleylka korantada

Sariiraha kuleylka korantada

Fiilooyinka dhalaalay barafka iyo dermooyinka

Saqafka saqafka dermooyinka kuleyliyaha ee iftiinka leh

Saqafka kululaynta iyo fiilooyinka

Qaboojiya fiilooyinka ilaalinta

Raadiyaha kulaylka korontada

Xadhkaha kuleylka PTFE

Kuleyliyeyaasha tuubada

Alaabta kale ee korantada yar Macluumaadka Alaabta:

| Darajo | CuNi44 | CuNi23 | CuNi10 | CuNi6 | CuNi2 | CuNi1 | CuNi8 | CuNi14 | CuNi19 | CuNi30 | CuNi34 | CuMn3 | |

| Cuprothal | 49 | 30 | 15 | 10 | 5 | ||||||||

| Isabellehutte | ISOTAN | Alloy 180 | Alloy 90 | Alloy 60 | Alloy 30 | Isa 13 | |||||||

| Halabuurka magaca ah% | Ni | 44 | 23 | 10 | 6 | 2 | 1 | 8 | 14 | 19 | 30 | 34 | - |

| Cu | Bal | Bal | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | Bal | Bal | Bal | Bal | |

| Mn | 1 | 0.5 | 0.3 | - | - | - | - | 0.5 | 0.5 | 1.0 | 1.0 | 3.0 | |

| Heerkulka shaqada ugu badan (uΩ/m at 20°C) | 0.49 | 0.3 | 0.15 | 0.10 | 0.05 | 0.03 | 0.12 | 0.20 | 0.25 | 0.35 | 0.4 | 0.12 | |

| Resistance (Ω/cmf at 68°F) | 295 | 180 | 90 | 60 | 30 | 15 | 72 | 120 | 150 | 210 | 240 | 72 | |

| Heerkulka shaqada ee ugu badan (°C) | 400 | 300 | 250 | 200 | 200 | 200 | 250 | 300 | 300 | 350 | 350 | 200 | |

| Cufnaanta (g/cm³) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| TCR(×10-6/°C) | <-6 | <16 | <50 | <60 | <120 | <100 | <57 | <30 | <25 | <10 | <0 | <38 | |

| Xoogga Jilitaanka (Mpa) | ≥420 | ≥350 | ≥290 | ≥250 | ≥220 | ≥210 | ≥270 | ≥310 | ≥340 | ≥400 | ≥400 | ≥290 | |

| Dheeraynta(%) | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | |

| EMF vs Cu uV/°C(0~100°C) | -43 | -34 | -25 | -12 | -12 | -8 | 22 | -28 | -32 | -37 | -39 | - | |

| Meesha dhalaalaysa (°C) | 1280 | 1150 | 1100 | 1095 | 1090 | 1085 | 1097 | 1115 | 1135 | 1170 | 1180 | 1050 | |

| Hanti Magnet | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | |

Halkan ku qor fariintaada oo noo soo dir

Qaybaha alaabta

-

Taleefanka

-

E-mailka

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare