Ku soo dhawoow boggayaga internetka!

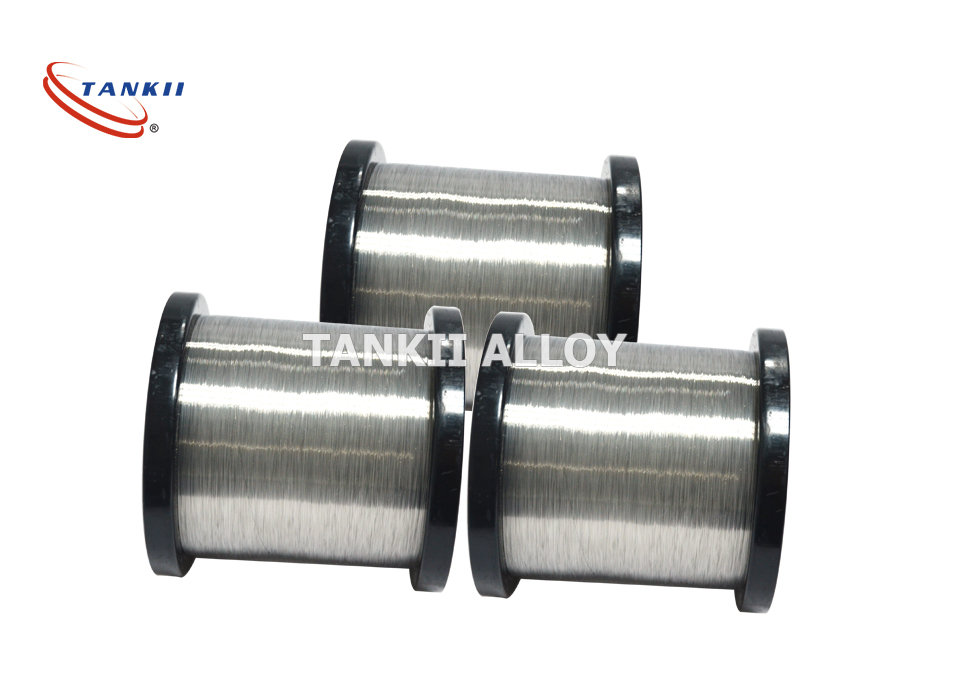

Silig kuleylin CRAL 205, walxo 1.4767 DIN 1.4767 silig u adkeysiga kulaylka

CRAL 205 waa daawaha birta-chromium-aluminium (FeCrAl daawaha) oo lagu garto iska caabin sare, isku-darka hoose ee iska caabbinta korontada, heerkulka hawlgalka oo sarreeya, iska caabbinta daxalka wanaagsan heerkulka sare. Waxay ku habboon tahay in loo isticmaalo heerkul ilaa 1300°C.

Codsiyada caadiga ah ee CRAL 205 waxaa loo isticmaalaa foornada korontada ee warshadaha, iyo jikada dhoobada korontada ku shaqeysa.

Halabuurka caadiga ah%

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Kale |

| Ugu badnaan | |||||||||

| 0.04 | 0.02 | 0.015 | 0.50 | Ugu badnaan 0.4 | 20.0-21.0 | Ugu badnaan 0.10 | 4.8-6 | Bal. | / |

Sifooyinka Jirka ee Caadiga ah

| Cufnaanta (g/cm3) | 7.10 |

| Iska caabinta korontada ee 20℃ (ohmm2/m) | 1.39 |

| Isugeynta gudbinta 20℃ (WmK) | 13 |

| Xoogga Laabista (Mpa) | 637-784 |

| Kordhinta | Ugu yaraan 16% |

| Xarig (HB) | 200-260 |

| Heerka Kala-soocidda Kala-duwanaanshaha Qaybta | 65-75% |

| Soo noqnoqoshada laabashada | Ugu yaraan 5 jeer |

| Isugeynta ballaarinta kulaylka | |

| Heerkulka | Isugeynta Ballaarinta Kulaylka x10-6/℃ |

| 20 ℃- 1000 ℃ | 16 |

| Awood kuleyl gaar ah | |

| Heerkulka | 20℃ |

| J/gK | 0.49 |

| Barta dhalaalaysa (℃) | 1500 |

| Heerkulka hawlgalka joogtada ah ee ugu badan (℃) | 1300 |

| sifooyinka birlabta | birlab ah |

Halkan ku qor fariintaada oo noo soo dir

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare