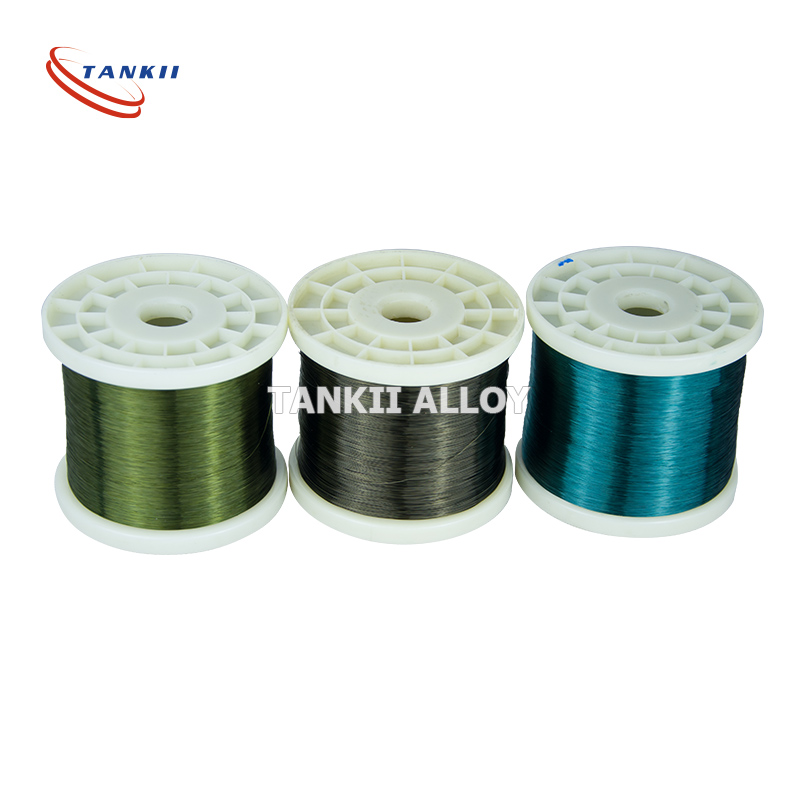

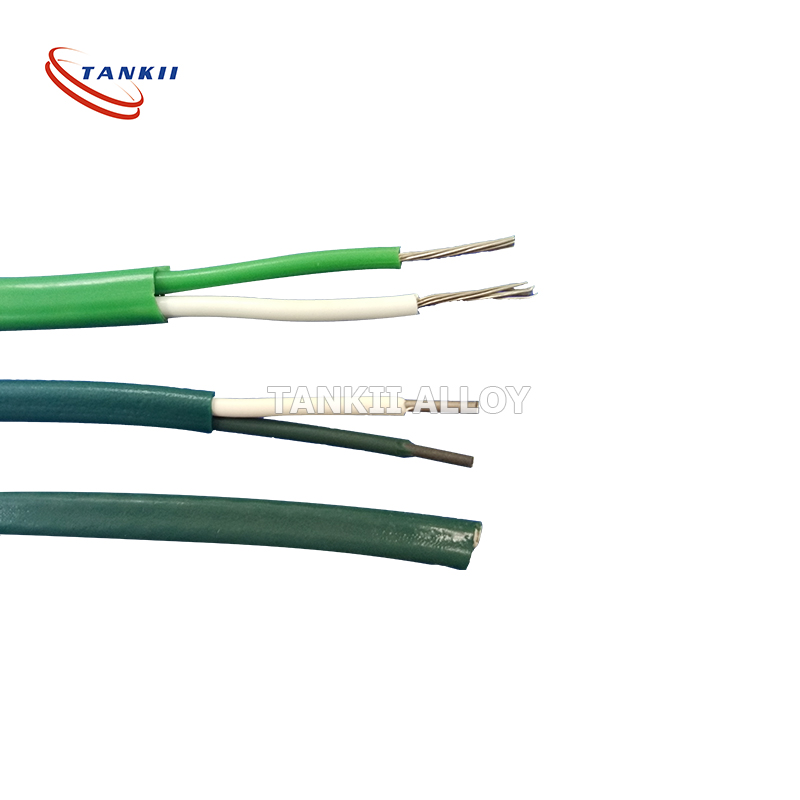

Fiilada naxaasta ah ee heerka kulaylka C / 200*C ANSI NOOCA MW35C ama IEC 317-13. Fiilada laba-daboolan ee Polyester-imide iyo Polyamide-imide ee dahaarka leh

silig naxaas ah fasalka kulaylka C/ 200*C ANSI NOOCA MW35C ama IEC 317-13. Polyester-imide iyopolyamide-imideSilig duuban oo labanlaab ah

Sharaxaadda Badeecada

Fiilooyinkan iska caabbinta ee dhaldhalaalka ah ayaa si ballaaran loogu isticmaalay iska caabbinta caadiga ah, baabuurta

qaybo, iska caabinta rogrogmada, iwm. iyadoo la isticmaalayodahaarkafarsamaynta ugu habboon codsiyadan, iyadoo si buuxda looga faa'iidaysanayo sifooyinka gaarka ah ee dahaarka dhaldhalaalka.

Intaa waxaa dheer, waxaan sameyn doonnaa dahaarka dhaldhalaalkadahaarkafiilooyin bir ah oo qaali ah sida siligga lacagta iyo platinum-ka marka la dalbado. Fadlan isticmaal wax soo saarkan marka la dalbado.

Nooca Siligga Nichrome

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

Nooca Dahaarka

| Magaca Dahaarka leh | Heerka Kulaylka°C (waqtiga shaqada 2000h) | Magaca Koodhka | Koodhka GB | NOOCA ANSI |

| Fiilo dhaldhalaal ah oo Polyurethane ah | 130 | UEW | QA | MW75C |

| Silig dhaldhalaal ah oo Polyester ah | 155 | PEW | QZ | MW5C |

| Silig dhaldhalaal ah oo Polyester-imide leh | 180 | EIW | QZY | MW30C |

| Silig labanlaab ah oo dhaldhalaal ah oo polyester-imide iyo polyamide-imide ah | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Silig dhaldhalaal ah oo Polyamide-imide ah | 220 | AIW | QXY | MW81C |

Nooca Wire Daawaha Bare

Daloolada aan samayn karno ee lagu dahaadhay birta waa silig daloolada naxaasta-nickel, silig Constantan, silig Manganin. Silig Kama, silig dalooyada NiCr, silig dalooyada FeCrAl iwm.

| ugu muhiimsan hanti nooca | Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | ||

| ugu muhiimsan kiimiko halabuurka | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | nasasho | nasasho | nasasho | nasasho | nasasho | nasasho | nasasho | nasasho | nasasho | nasasho | nasasho | ||

| ugu badan shaqeynaya heerkulka | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| cufnaanta g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| iska caabin heerkul ah 20 °c | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.20± 5% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | ||

| heerkulka isku-dheelitirka iska caabin | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| jilicsanaan xoogga mp | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | ||

| dheereyn | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| dhalaalid dhibic °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| isku-dheelitirka conductivity | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

Fiilada kuleylka ee nicr8020

1. Ku saabsan fiilada Nichrome

Daawaha Nichrome waxaa ka mid ah nikkel saafi ah, daawaha NiCr, daawaha Fe-Cr-Al iyo daawaha nikkel naxaasta ah.

Daloolada chrome-ka ee nikkel: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nikkel saafi ah Ni200 iyo Ni201

2. Faa'iidada ugu weyn iyo Codsiga

1. Nikkel-chromium, dahaarka nikkel-chromium oo leh iska caabin sare oo deggan, iska caabin daxalka, iska caabin oksaydheynta dusha sare waa wanaagsan tahay, heerkul sare iyo xoog dhul gariir ah oo ka wanaagsan, dabacsanaan wanaagsan, shaqeyn wanaagsan iyo alxan.

2. Badeecadahayagu waxay si ballaaran u khuseeyaan warshadaha kiimikada, farsamada birta, warshadaha galaaska, warshadaha dhoobada, aagga qalabka guriga iyo wixii la mid ah.

3. Halabuurka kiimikada:

| Summada | Halabuurka kiimikada | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Ma aha wax ka badan | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | hadho | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | hadho |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | hadho |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | hadho |

Marka badeecadu ay ku sugan tahay heerka "M", waa in la raaco heerka GB/T1234-1995 ee caadiga ah

Iska caabin:

| Summada | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| Dhexroorka mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| iska caabin (20°C) uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare