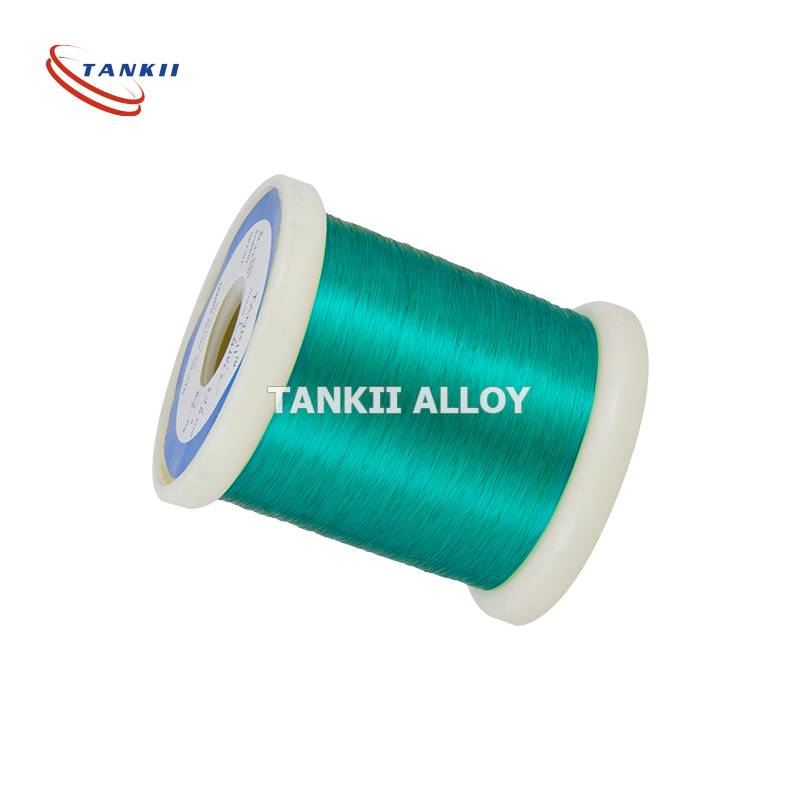

Silig naxaas ah oo wareegsan oo naxaas ah oo lagu dahaadhay naxaas/boostereyl wax laga beddelay

Fasalka Fnayloon/wareeg wareeg ah oo dhaldhalaal ah oo wax laga beddelaysilig naxaas ah

Sharaxaadda Badeecada

Fiilooyinkan iska caabbinta ee dhaldhalaalka ah ayaa si ballaaran loogu isticmaalay iska caabbinta caadiga ah, baabuurta

qaybo, iska caabinta rogrogmada, iwm. iyadoo la isticmaalayodahaarkafarsamaynta ugu habboon codsiyadan, iyadoo si buuxda looga faa'iidaysanayo sifooyinka gaarka ah ee dahaarka dhaldhalaalka.

Intaa waxaa dheer, waxaan sameyn doonnaa dahaarka dhaldhalaalkadahaarkafiilooyin bir ah oo qaali ah sida siligga lacagta iyo platinum-ka marka la dalbado. Fadlan isticmaal wax soo saarkan marka la dalbado.

Nooca fiilada Daawaha qaawan

Daloolada aan samayn karno ee lagu dahaadhay birta waa silig daloolada naxaasta-nickel, silig Constantan, silig Manganin. Silig Kama, silig dalooyada NiCr, silig dalooyada FeCrAl iwm.

Nooca dahaarka

| Magaca Dahaarka leh | Heerka Kulaylka°C (waqtiga shaqada 2000h) | Magaca Koodhka | Koodhka GB | NOOCA ANSI |

| Fiilo dhaldhalaal ah oo Polyurethane ah | 130 | UEW | QA | MW75C |

| Silig dhaldhalaal ah oo Polyester ah | 155 | PEW | QZ | MW5C |

| Silig dhaldhalaal ah oo Polyester-imide leh | 180 | EIW | QZY | MW30C |

| Silig labanlaab ah oo dhaldhalaal ah oo polyester-imide iyo polyamide-imide ah | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Silig dhaldhalaal ah oo Polyamide-imide ah | 220 | AIW | QXY | MW81C |

Waxyaabaha Kiimikada, %

| Cu | Bi | Sb | As | Fe | Ni | Pb | S | Zn | Tilmaamaha ROHS | |||

| Cd | Pb | Hg | Cr | |||||||||

| 99.90 | 0.001 | 0.002 | 0.002 | 0.005 | - | 0.005 | 0.005 | - | ND | ND | ND | ND |

Sifooyinka Jirka

| Barta Dhalmada - Liquidus | 1083ºC |

| Barta Dhalmada - Solidis | 1065ºC |

| Cufnaanta | 8.91 gm/cm3@ 20 ºC |

| Cufis-jiidad Gaar ah | 8.91 |

| Iska caabinta Korontada | 1.71 microhm-cm @ 20 ºC |

| Koronto Qaboojiye** | 0.591 MegaSiemens/cm @ 20 ºC |

| Qaboojinta Kulaylka | 391.1 W/m ·oK heerkul ah 20 C |

| Isugeynta Ballaarinta Kulaylka | 16.9 · 10-6 perºC(20-100 ºC) |

| Isugeynta Ballaarinta Kulaylka | 17.3 · 10-6 perºC(20-200 ºC) |

| Isugeynta Ballaarinta Kulaylka | 17.6·10-6 perºC(20-300 ºC) |

| Awoodda Kulaylka Gaarka ah | 393.5 J/kg ·oK oo ah 293 K |

| Modulus of Relaxity in Xiisadda | 117000 Mpa |

| Modulus-ka Adkaanta | 44130 Mpa |

Codsiga bir-bireed naxaas ah

1) Biyo-xireennada korontada iyo kuwa korontada ku shaqeeya, iyo kuwa lagu beddelo

2) Qaababka Rasaasta

3) Xidhiidhiyayaasha iyo ul-wareer

3) Goobta PCB

4) Fiilada isgaarsiinta, qalabka ilaalinta fiilooyinka, qalabka taleefanka gacanta ee ugu weyn

5) Lamination-ka wax soo saarka baytariga Ion oo leh filim PI ah

6) Qalabka ururiyaha PCB (elektrode backback)

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare