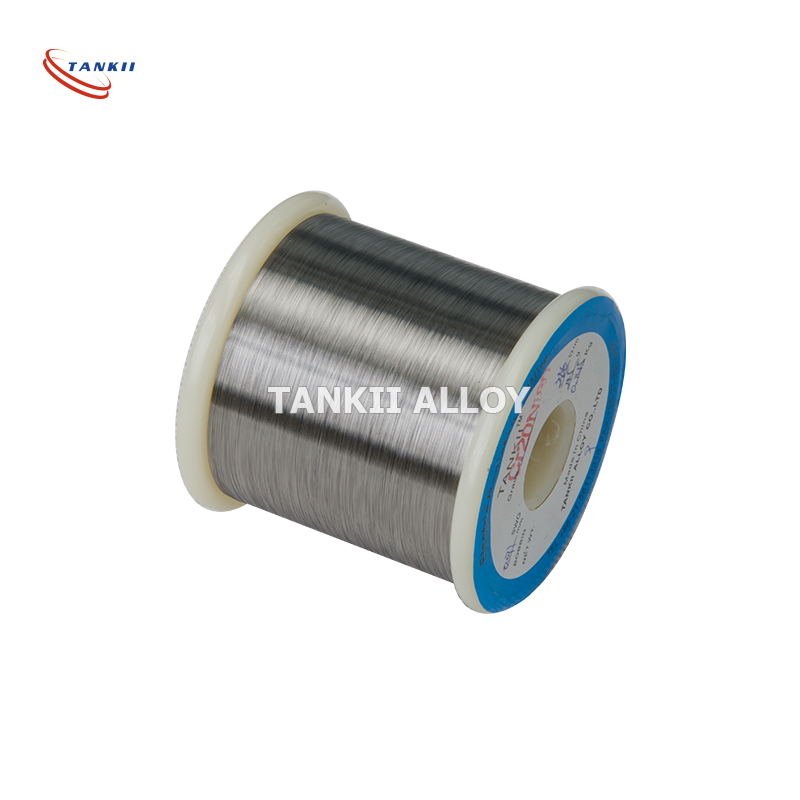

Shiinaha Soo Saara Silig Nikkel ah oo saafi ah Ni200 oo loogu talagalay Filament

Shiinaha Soo Saarista Saafi ahSilig Nikkel ahFiilada Ni200 ee loogu talagalay Filament

Shirkadda Shanghai TANKII Alloy Material Co., Ltd. waxay diiradda saareysaa soo saarista Nichrome Alloy, siligga Thermocouple, FeCrAl Alloy, Precision Alloy, CopperNikkelDaawaha, Daawaha Buufinta Kulaylka, iwm oo ah qaab silig, xaashi, cajalad, xarig, ul iyo saxan.

Saafi ahNikkel Silig

1.> wuxuu leeyahay xoog wanaagsan iyo astaamo iska caabin hooseeya marka heerkulku sarreeyo.

2.>Dabacsanaan: jilicsan; adag; 1/2 adag

3.> Wareegga wax soo saarka: 3-7 maalmood

4.> Taxane ahSilig nickel saafi ah: silig nikkel 200 ah, silig nikkel 201 ah.

5.> Nadiifnimada waxaa la gaari karaa ilaa 99.99%, aadka u khafiifsan waxaa la gaari karaa ilaa 0.02mm

Astaamaha

1.> Iyada oo leh alxan, gudbin sare, isku-xidhka ballaarinta toosan ee ku habboon

2.> Xoog wanaagsan, iska caabin hooseeya heerkulka sare

3.> Bar dhalaal sare, iska caabin daxalka, sifooyin farsamo oo wanaagsan, xaaladda kulul iyo qabow waxay leedahay habayn cadaadis oo wanaagsan, si fudud loo dejin karo gaaska, raadiyaha, iftiinka korontada, wax soo saarka mashiinnada, warshadaha kiimikada, aaladaha elektaroonigga ah ee faakiyuumka waa agab muhiim ah oo qaab dhismeed ah.

Halabuurka Kiimikada Siliga Nikel ee Saafiga ah:

| Heerka Nikkel | Ni+Co | Cu | Si | Mn | C | Cr | S | Fe | Mg |

| ≥ | ≤ | ||||||||

| Ni201 | 99.0 | .25 | .3 | .35 | .02 | .2 | .01 | .3 | - |

| Ni200 | 99.0 | .25 | .3 | .35 | .15 | .2 | .01 | .3 | - |

![]()

![]()

![]()

![]()

Adeeggayaga:

1.> Waxaan ku siin karnaa muunad bilaash ah oo loogu talagalay tijaabinta laakiin xamuulka ayaa ku yaal adiga.

2.> Shahaadada tijaabada warshadda ayaa la bixin doonaa ka dib marka la soo saaro, haddii loo baahdo.

3.>Habab wanaagsan oo lagu xidho alaabta si aanay waxyeello u soo gaarin inta la keenayo

4.>Waxaan la shaqeynaa shirkado badan oo caan ah oo gudbiya gawaarida, waxaan isku dayi doonnaa sida ugu wanaagsan ee aan u dooran karno habka gaadiidka ee macaamiisheenna ugu habboon, ugu habboon, ugu dhaqsaha badan, uguna raqiisan.

Taxanaheena kale eesilig kuleyliye koronto

| Nooca Daawaha | Dhexroorka (mm) | Iska caabin (μΩm) (20°C) | Gariir Xoog (N/mm²) | Kordhinta (%) | Laablaabid Waqtiyada | Ugu badnaan. Joogto ah Adeegga Heerkulka (°C) | Nolosha Shaqada (saacadaha) |

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

![]()

![]()

![]()

![]()

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare