Alkrothal 720 No.1 JR FeCrAl Alloy oo loogu talagalay iska caabbinta biriiga

Alkrothal 720 Lambarka 1aad ee JRiska caabbinta biriiga

Codsiyada caadiga ah ee Alkrothal 720 waxay ku jiraan rheostats, iska caabbinta biriiga, iwm. Waxaa sidoo kale loo isticmaalaa sidii walxaha kuleylinta korantada ee codsiyada warshadaha.

Alkrothal 720 waa bir ferritic-chromium-aluminium ah (aluminium-ka FeCrAl) oo loogu talagalay in lagu isticmaalo heerkul ilaa 1000°C (1830°F).

Falanqaynta Magacaaban

| Cr | Al | Fe |

| 12.0~15.0 | 4.0~6.0 | Dheelitirnaan |

Sifooyinka Farsamada

| Heerkulka Adeegga Joogtada ah ee Ugu Badan: Adkeysiga 20ºC: Cufnaanta: Qaboojinta Kulaylka: Isugeynta Ballaarinta Kulaylka: Barta Dhalmada: Kordhinta: Qaab-dhismeedka Micrographic: Hantida Birlabta: | 950ºC 1.25ohm mm2/m 7.40g/cm3 52.7 KJ/m·h·ºC 15.4×10-6/ºC (20ºC ~ 1000ºC) 1450ºC Ugu yaraan 16% Ferrite birlab ah |

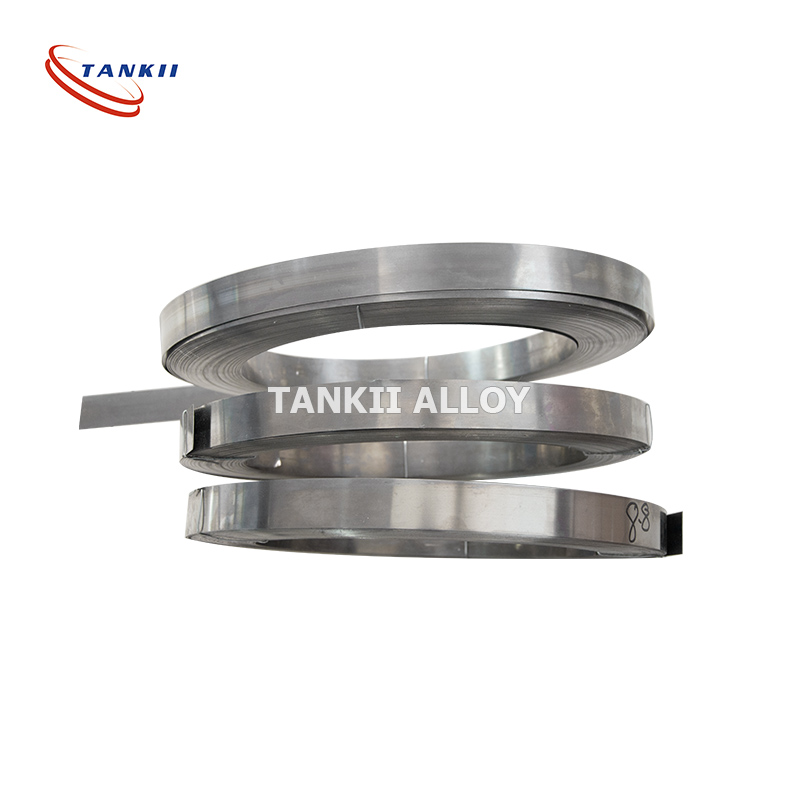

Cabbirka: Dhumucda 0.01-7mm, ballaca 0.5-1000mm

Dusha sare: BA, 2B

Adkaanta: Jilicsan, Badh adag, adag

Waxaa si ballaaran loogu isticmaalay sidii resisor weyn oo awood leh iyo walxaha kululaynta foornada.

Waxay leedahay awood kulul oo ka yar daawaha Tophet laakiin aad ayay uga badan tahay dhalaalka.

Hal qayb oo ka mid ah Shanghai TANKII ALOY MATERIAL Co., Ltd.

Soo-saaraha FECRAL IYO ALCHROME Alloy ee Shiinaha, ahna xirfadleyda ugu badan adduunka

Waxaan sidoo kale soo saarnaa darajooyin ka hooseeya:

0Cr15Al5 iyo 0Cr19Al3, iwm.

| Halabuurka Kiimikada iyo Hantida ugu Muhiimsan ee Daawaha Iska caabinta Fe-Cr-Al | ||||||||

| Heerka Guryaha | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Halabuurka Kiimikada ugu Muhiimsan (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | fursad | fursad | fursad | fursad | fursad | fursad | fursad | |

| Fe | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Heerkulka Adeegga Joogtada ah ee Ugu Badan (oC) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Adkeysiga 20oC (Ωmm2/m) | 1.25 ±0.08 | 1.42 ±0.06 | 1.42 ±0.07 | 1.35 ±0.07 | 1.23 ±0.07 | 1.45 ±0.07 | 1.53 ±0.07 | |

| Cufnaanta (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Qaboojinta Kulaylka | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| (KJ/m@h@oC) | ||||||||

| Isugeynta Ballaarinta Kulaylka (α × 10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Barta Dhalmada ee Qiyaas ahaan (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Xoog La'aan (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Kordhinta (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Kala duwanaanshaha Qaybta | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Heerka hoos u dhaca (%) | ||||||||

| Soo noqnoqoshada laabashada (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Adkaanta (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Waqtiga Adeegga ee Joogtada ah | no | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Qaab-dhismeedka Micrographic | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Hantida Birlabta ah | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare