Ku soo dhawoow boggayaga internetka!

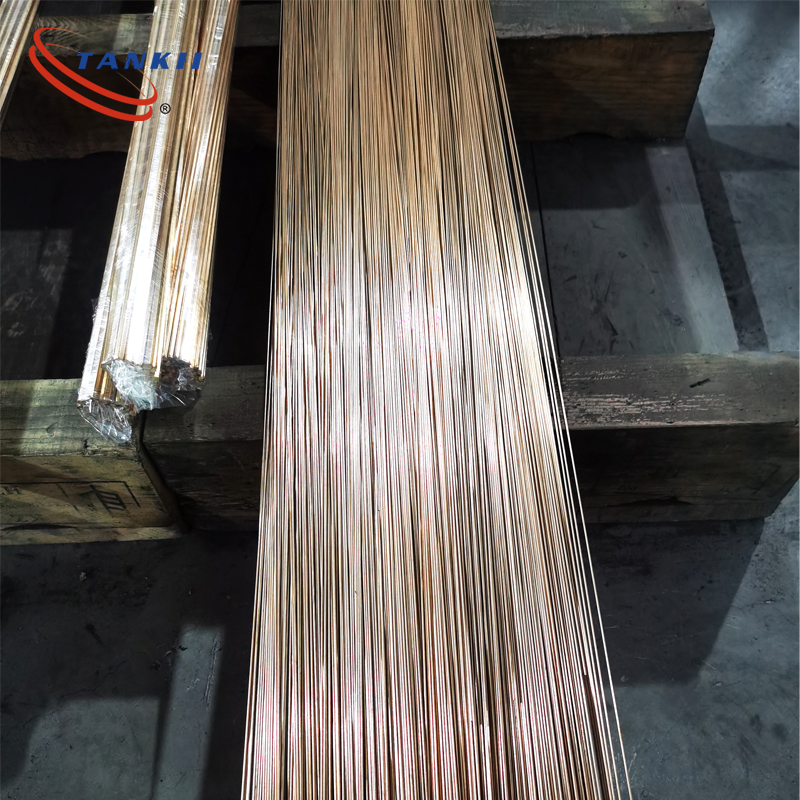

5.0mm Ni80Cr20 Bar oo loogu talagalay Walxaha Tubularka ee Birta ah ee la dahaadhay

NiCr 8020 (2.4869) waxaa loo isticmaalaa walxaha kuleylinta korontada ee qalabka guryaha iyo foornada warshadaha. Isticmaalka caadiga ah waa biraha fidsan, mashiinnada kaawiya, kuleyliyeyaasha biyaha, maydka qaabaynta balaastikada, biraha alxanka, walxaha tuubooyinka birta ah ee dahaarka leh iyo walxaha kartoonada.

- qaybaha korontada iyo qaybaha elektarooniga ah.

- walxaha kuleyliyaha korontada (isticmaalka guriga iyo warshadaha).

- Foornooyinka warshadaha ilaa 1200 °C.

- fiilooyinka kululaynta, roogagga iyo fiilooyinka

| Fasal | Ni80Cr20 | Ni70Cr30 | Ni60Cr23 | Ni60Cr15 | Ni35Cr20 | Karma | Evanohm | |

| Halabuurka magacaaban% | Ni | Bal | Bal | 58.0-63.0 | 55.0-61.0 | 34.0-37.0 | Bal | Bal |

| Cr | 20.0-23.0 | 28.0-31.0 | 21.0-25.0 | 15.0-18.0 | 18.0-21.0 | 19.0-21.5 | 19.0-21.5 | |

| Fe | ≦1.0 | ≦1.0 | Bal | Bal | Bal | 2.0-3.0 | - | |

| Al1.0-1.7 Ti 0.3-0.5 | Al2.7-3.2 Mn0.5-1.5 | Al2.7-3.2 Cu2.0-3.0 Mn0.5-1.5 | ||||||

| Heerkulka ugu badan ee hawlgalka (°C) | 1200 | 1250 | 1150 | 1150 | 1100 | 300 | 400 | |

| Adkeysiga (Ω/cmf, 20℃) | 1.09 | 1.18 | 1.21 | 1.11 | 1.04 | 1.33 | 1.33 | |

| Adkeysiga (uΩ/m, 60°F) | 655 | 704 | 727 | 668 | 626 | 800 | 800 | |

| Cufnaanta (g/cm³) | 8.4 | 8.1 | 8.4 | 8.2 | 7.9 | 8.1 | 8.1 | |

| Qaboojinta Kulaylka (KJ/m·h·℃) | 60.3 | 45.2 | 45.2 | 45.2 | 43.8 | 46.0 | 46.0 | |

| Isugeynta Ballaarinta Toosan(×10¯6/℃) 20-1000℃) | 18.0 | 17.0 | 17.0 | 17.0 | 19.0 | - | - | |

| Barta Dhalmada (℃) | 1400 | 1380 | 1370 | 1390 | 1390 | 1400 | 1400 | |

| Adkaanta (Hv) | 180 | 185 | 185 | 180 | 180 | 180 | 180 | |

| Xoog Laab Laab (N/mm)2 ) | 750 | 875 | 800 | 750 | 750 | 780 | 780 | |

| Kordhinta (%) | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | 10-20 | 10-20 | |

| Qaab-dhismeedka Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | austenit | |

| Hantida Magnetic-ga | Aan ahayn | Aan ahayn | Aan ahayn | Si yar | Aan ahayn | Aan ahayn | Aan ahayn | |

| Nolosha Degdegga ah (h/℃) | ≥81/1200 | ≥50/1250 | ≥81/1200 | ≥81/1200 | ≥81/1200 | - | - | |

Halkan ku qor fariintaada oo noo soo dir

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare