2% Fiilada Korontada ee Nikkel Plated ASTM B355 ee Elektarooniga Gawaarida

Faa'iidada Badeecada:

1. Alxanka waa mid aad u fiican; alxanka ferrochrome, alxanka hirarka iyo alxanka dib-u-socodka ayaa si aan kala sooc lahayn loogu qancin karaa.

2. Dahaadhku waa dhalaalaya, siman yahay, siman yahay oo qoyan yahay; xoogga isku xidhka iyo joogtayntuna waa wanaagsan tahay.

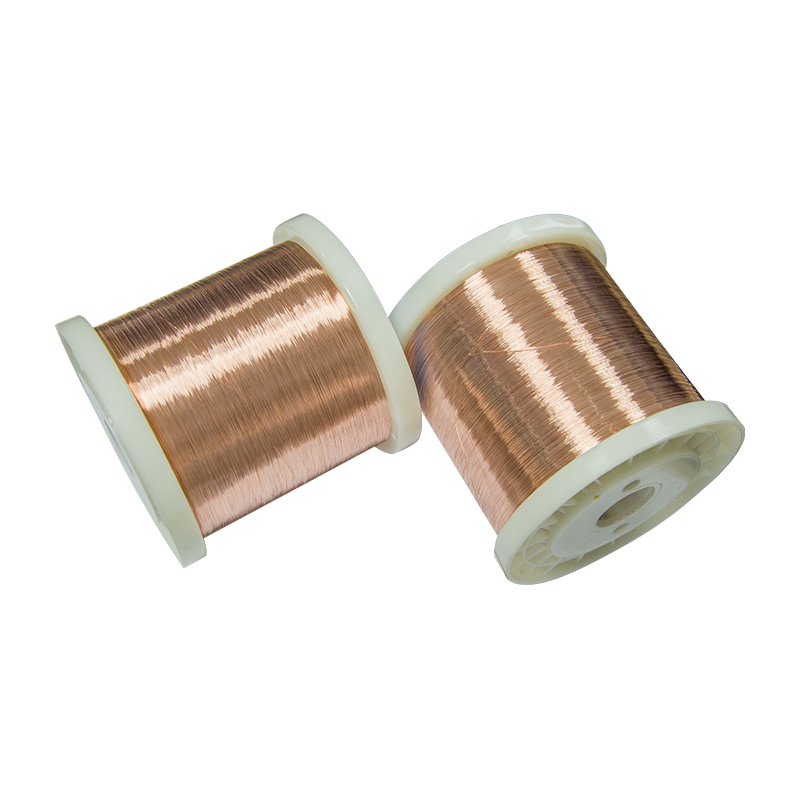

3. Xudunta fiilada waxay ka samaysan tahay naxaas tayo sare leh oo 99.9% saafi ah, taasoo bixisa koronto aad u fiican iyo xasillooni kuleyl.

4. Lakabka dibadda wuxuu ka kooban yahay dahaadh nikkel ah, kaas oo kor u qaada iska caabbinta daxalka, adkaanta, iyo cimri dhererka fiilada.

5. U adkeysi xaaladaha adag, oo ay ku jiraan heerkulka sare, gariirka, iyo walbahaarka farsamada, oo ku habboon codsiyada sida warshadaha badda iyo baabuurta.

6. Sifooyinka farsamada waxaa si gaar ah loogu habeyn karaa, si loo hubiyo in si deggan oo la isku halleyn karo loogu isticmaalo xaaladaha kala duwan.

Silig Naxaas ah oo Nikkel lagu dahaadhayAstaamaha:

| Nikkel lagu dahaadhaysilig naxaas ah | |||

| Dhexroorka magacaaban (d) | Kala duwanaanshaha la oggol yahay ee dhexroorka | ||

| mm | mm | ||

| 0.05≤d <0.25 | +0.008/-0.003 | ||

| 0.25≤d <1.30 | +3%d/-1%d | ||

| 1.30≤d≤3.26 | +0.038/-0.013 | ||

| Dhexroorka magacaaban (d) | Shuruudaha Tijaabada (ugu yaraan %) | Shuruudaha Tijaabada (ugu yaraan %) | |

| mm | Fasallada 2, 4, 7 iyo 10 | Fasalka 27aad | |

| 0.05≤d≤0.10 | 15 | 8 | |

| 0.10 | 15 | 10 | |

| 0.23 | 20 | 15 | |

| 0.50 | 25 | 20 | |

| Fasalka, % Nikkel | Shuruudaha iska caabinta korontada | Gudbinta | |

| Ω·mm²/dareere 20°C (Daqiiqad) | % IACS heerkulka 20°C (ugu yaraan) | ||

| 2 | 0.017960 | 96 | |

| 4 | 0.018342 | 94 | |

| 7 | 0.018947 | 91 | |

| 10 | 0.019592 | 88 | |

| 27 | 0.024284 | 71 | |

| Dhumucda Dahaadhka | |||

| Dhumucda lakabka dahaadhka nikkelka waa inay buuxisaa heerarka GB/T11019-2009 iyo ASTM B335-2016, macaamiishuna waxay yeelan karaan shuruudo kala duwan. | |||

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare