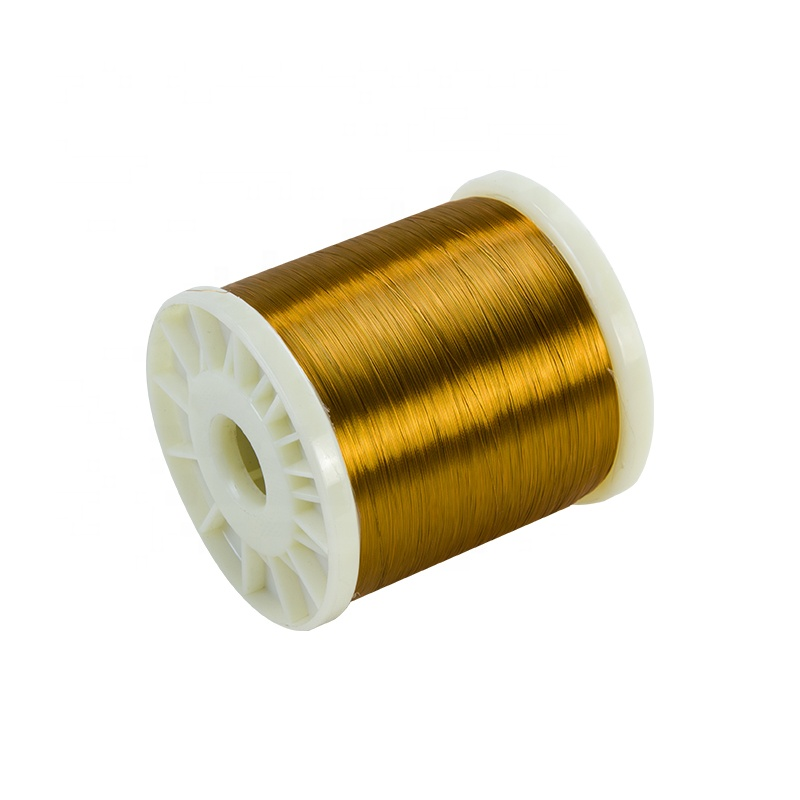

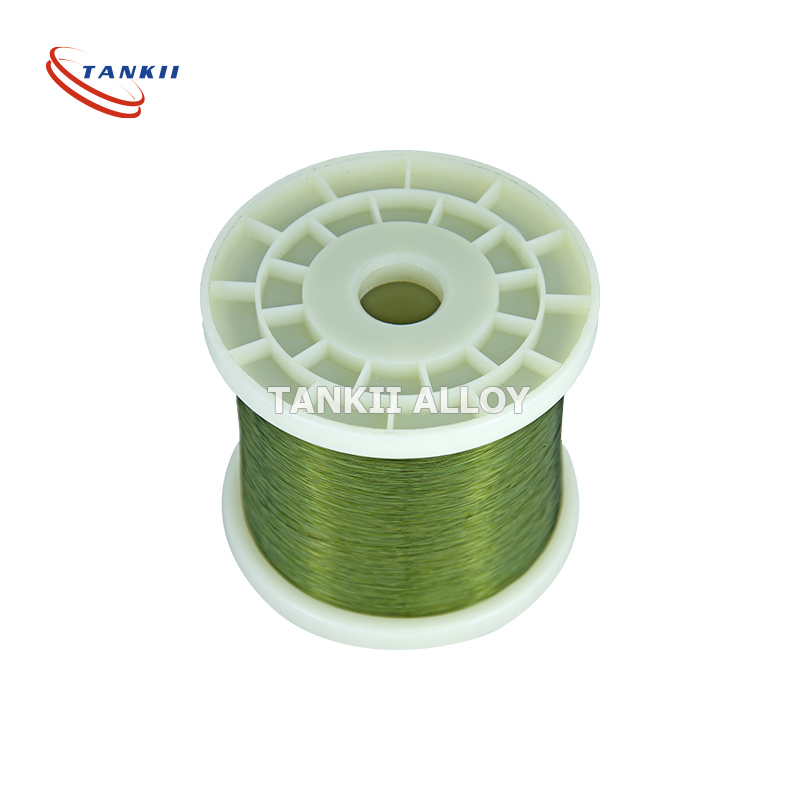

0.2mm 130 Fasalka Silig Enameleed oo leh Midabo wareegsan oo naxaas ah Manganin

130 Silig oo midab leh oo wareegsan oo ah naxaas ah oo Manganin ah

1. Sharaxaadda Guud ee Agabka

Daawaha nikkel-ka naxaasta ah, kaas oo leh iska caabin koronto oo hooseeya, u adkaysta kulaylka iyo u adkaysta daxalka, si fudud loo farsamayn karo loona alxami karo rasaasta. Waxaa loo isticmaalaa in lagu sameeyo qaybaha muhiimka ah ee ku jira gudbinta xad-dhaafka ah ee kulaylka, jabiyaha wareegga kulaylka ee iska caabinta hooseeya, iyo qalabka korontada. Sidoo kale waa walxo muhiim u ah fiilada kuleylinta korontada. Waxay la mid tahay nooca cupronickel. Inta badan ee Nickel uu ka kooban yahay, ayaa dusha sare ee cad cad oo badan uu noqon doonaa.

3. Halabuurka Kiimikada iyo Hantida ugu Muhiimsan ee Daawaha Cu-Ni ee Iska caabinta Yar

| Astaamaha Fasalka | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Halabuurka Kiimikada ugu Muhiimsan | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Heerkulka Adeegga Joogtada ah ee Ugu Badan (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Adkeysiga 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Cufnaanta (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Qaboojinta Kulaylka (α × 10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Xoogga Laabista (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Barta Dhalmada ee Qiyaas ahaan (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Qaab-dhismeedka Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | |

| Hantida Birlabta ah | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | |

| Astaamaha Fasalka | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Halabuurka Kiimikada ugu Muhiimsan | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Heerkulka Adeegga Joogtada ah ee Ugu Badan (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Adkeysiga 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Cufnaanta (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Qaboojinta Kulaylka (α × 10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Xoogga Laabista (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Barta Dhalmada ee Qiyaas ahaan (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Qaab-dhismeedka Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | |

| Hantida Birlabta ah | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | aan ahayn | |

2. Hordhac iyo codsiyo ku saabsan fiilada la isku dhejiyay

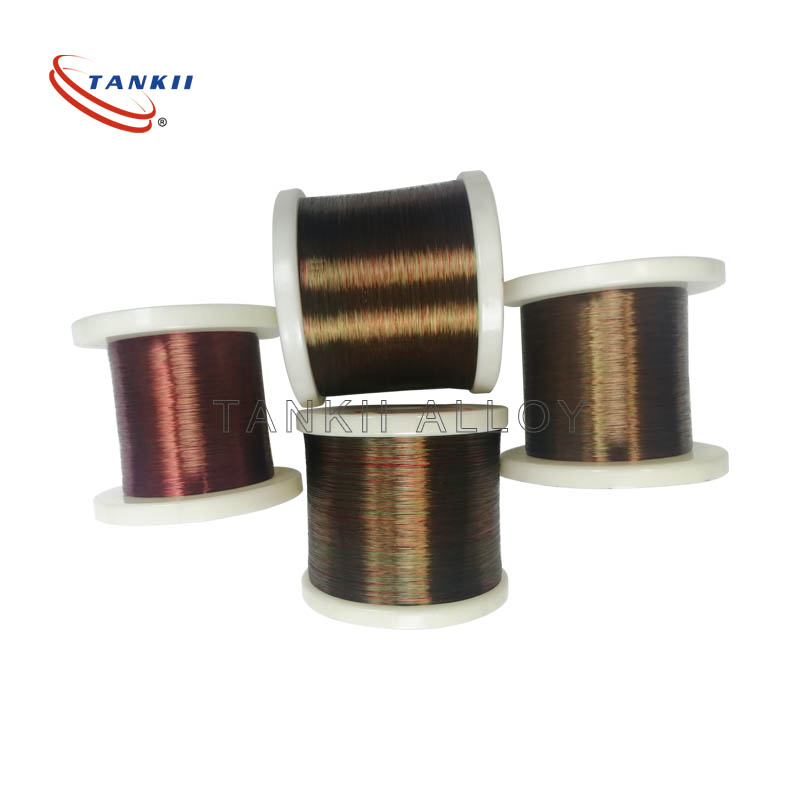

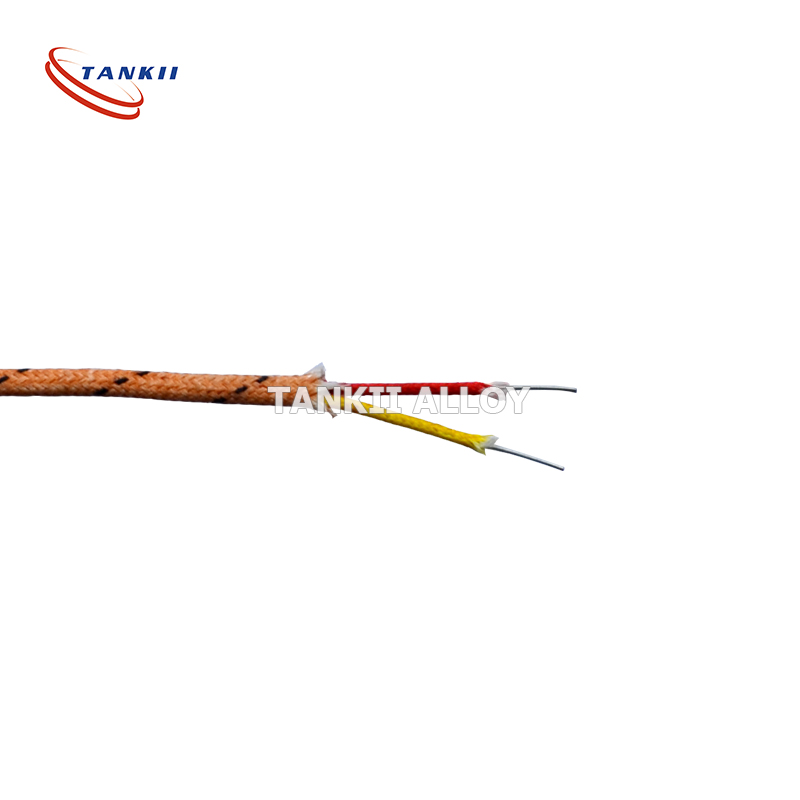

Inkasta oo lagu tilmaamay "dhagax-madow",silig dhaldhalaal ahDhab ahaantii, laguma dahaadhin lakab rinji dhaldhalaal ah ama dhaldhalaal bir ah oo laga sameeyay budada galaaska ee la isku daray. Fiilada birdhalaalka casriga ah waxay caadi ahaan isticmaashaa hal ilaa afar lakab (haddii ay tahay silig nooca afar-film ah) oo dahaarka filimka polymer-ka ah, badanaa laba isku-dhafan oo kala duwan, si ay u bixiso lakab dahaar adag oo joogto ah. Filimada dahaarka siligga birdhalaalka ah waxay isticmaalaan (si ay u kordhiyaan heerkulka) polyvinyl rasmi ah (Formar), polyurethane, polyimide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (ama amide-imide), iyo polyimide. Fiilada birdhalaalka ee dahaarka leh ee Polyimide waxay awood u leedahay inay shaqeyso ilaa 250 °C. Dahaarka siligga birdhalaalka ah ee qaro weyn ama afar-geesoodka ah waxaa badanaa lagu kordhiyaa iyadoo lagu duubo cajalad polyimide heerkul sare leh ama fiberglass ah, wareegyada la dhammeeyayna badanaa waxaa lagu shubaa faakiyuum varnish si loo hagaajiyo xoogga dahaarka iyo isku halaynta muddada dheer ee dahaarka.

Galoolada is-taageera waxaa lagu dhejiyay silig lagu dahaadhay ugu yaraan laba lakab, kan ugu sarreeya waa thermoplastic kaas oo isku xira wareegyada marka la kululeeyo.

Noocyada kale ee dahaarka sida dun fiberglass ah oo leh varnish, warqad aramid ah, warqad kraft ah, mica, iyo filim polyester ah ayaa sidoo kale si weyn loogu isticmaalaa adduunka oo dhan codsiyada kala duwan sida transformers-ka iyo reactors-ka. Qaybta maqalka, silig dhisme qalin ah, iyo dahaar kale oo kala duwan, sida cudbiga (mararka qaarkood waxaa ku dhex milma nooc ka mid ah wakiilka isku-xidhka/qafiifka, sida shinnida) iyo polytetrafluoroethylene (PTFE). Agabka dahaarka ee hore waxaa ka mid ahaa suuf, warqad, ama xariir, laakiin kuwani waxay waxtar u leeyihiin oo keliya codsiyada heerkulka hooseeya (ilaa 105°C).

Si loo fududeeyo wax soo saarka, qaar ka mid ah fiilooyinka birlabta ee heerkulka hooseeya leh waxay leeyihiin dahaadh oo laga saari karo kulaylka alxanka. Taas macnaheedu waa in isku xirka korontada ee darafyada la samayn karo iyada oo aan marka hore laga saarin dahaarka.

Qaybaha alaabta

-

Telefoon

-

Iimayl

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sare